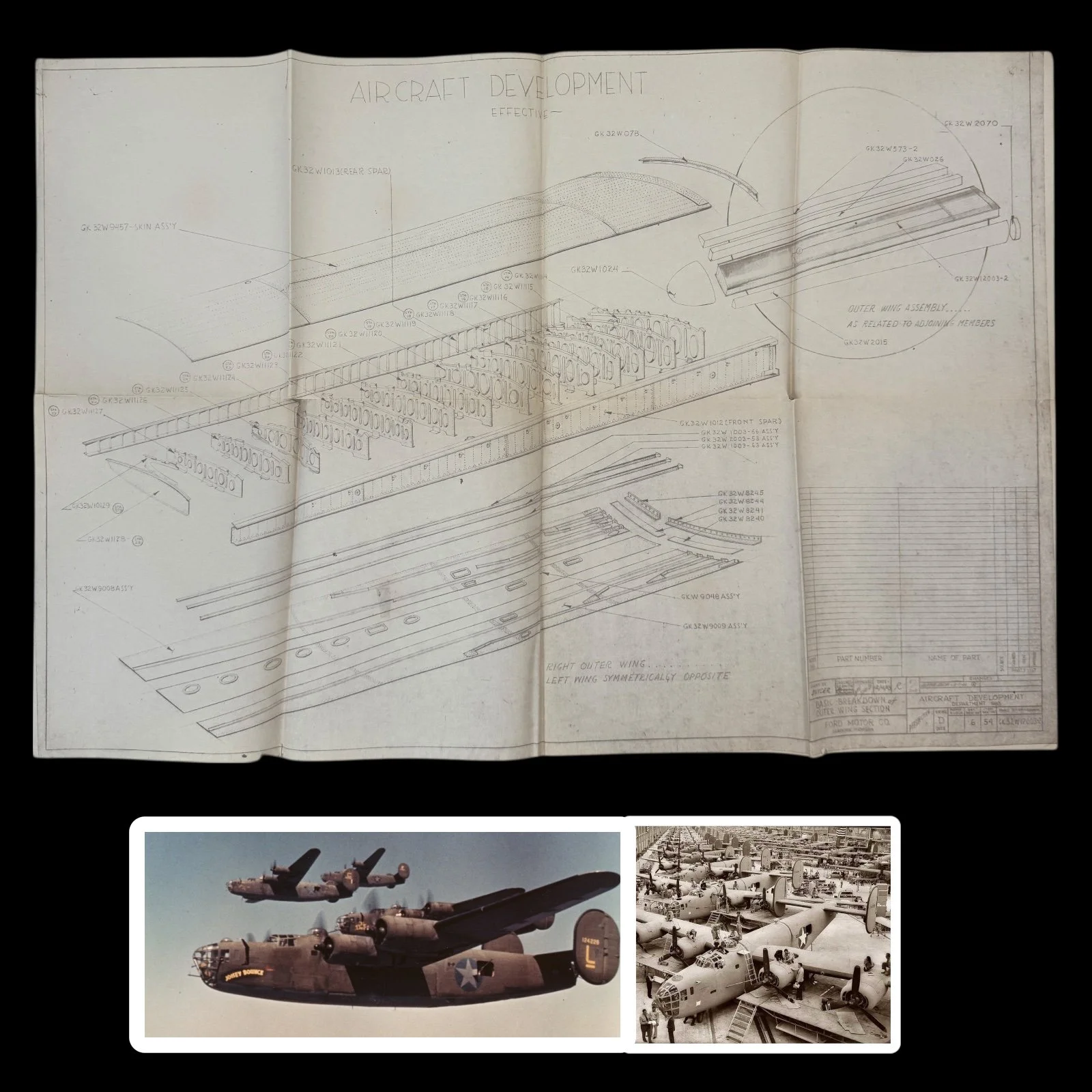

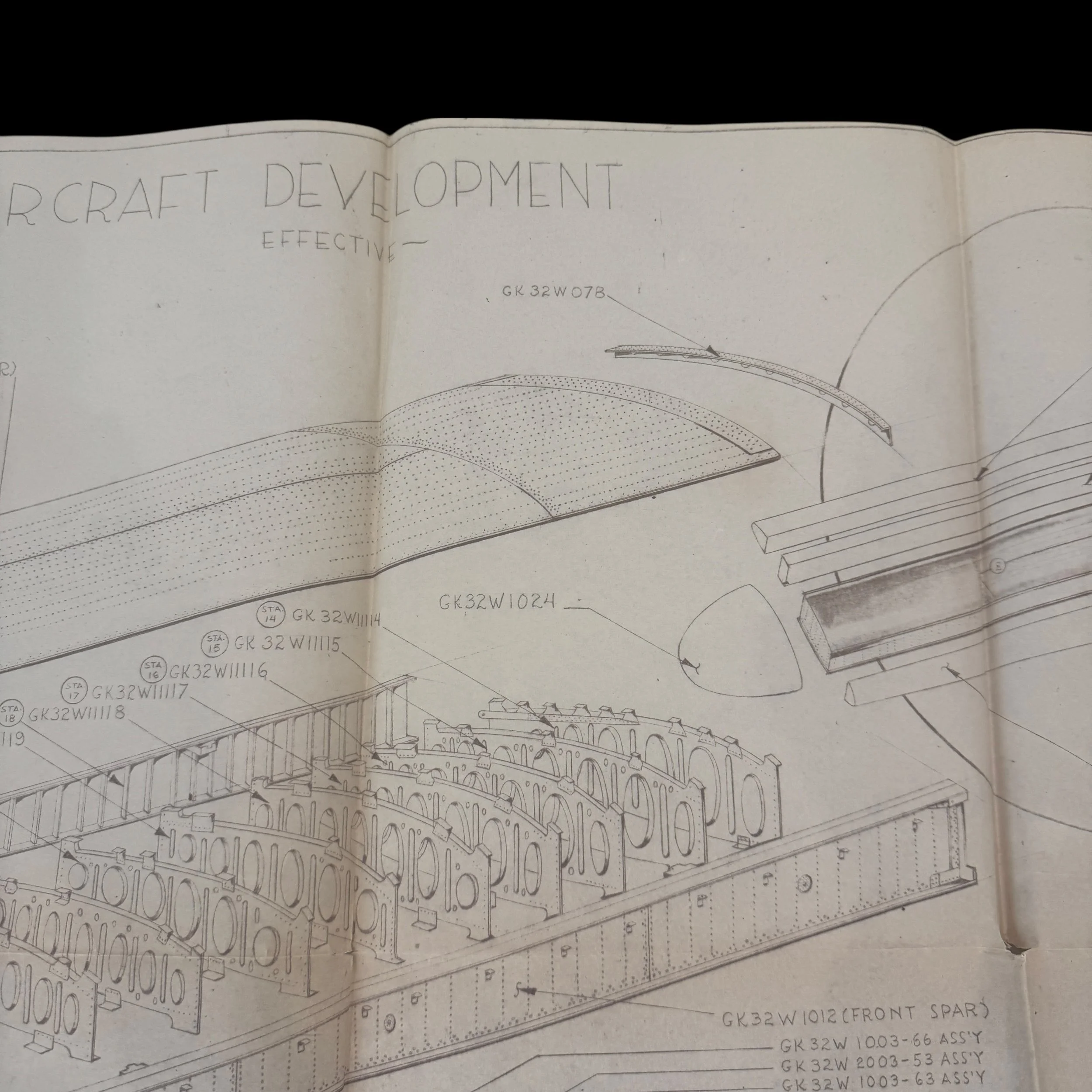

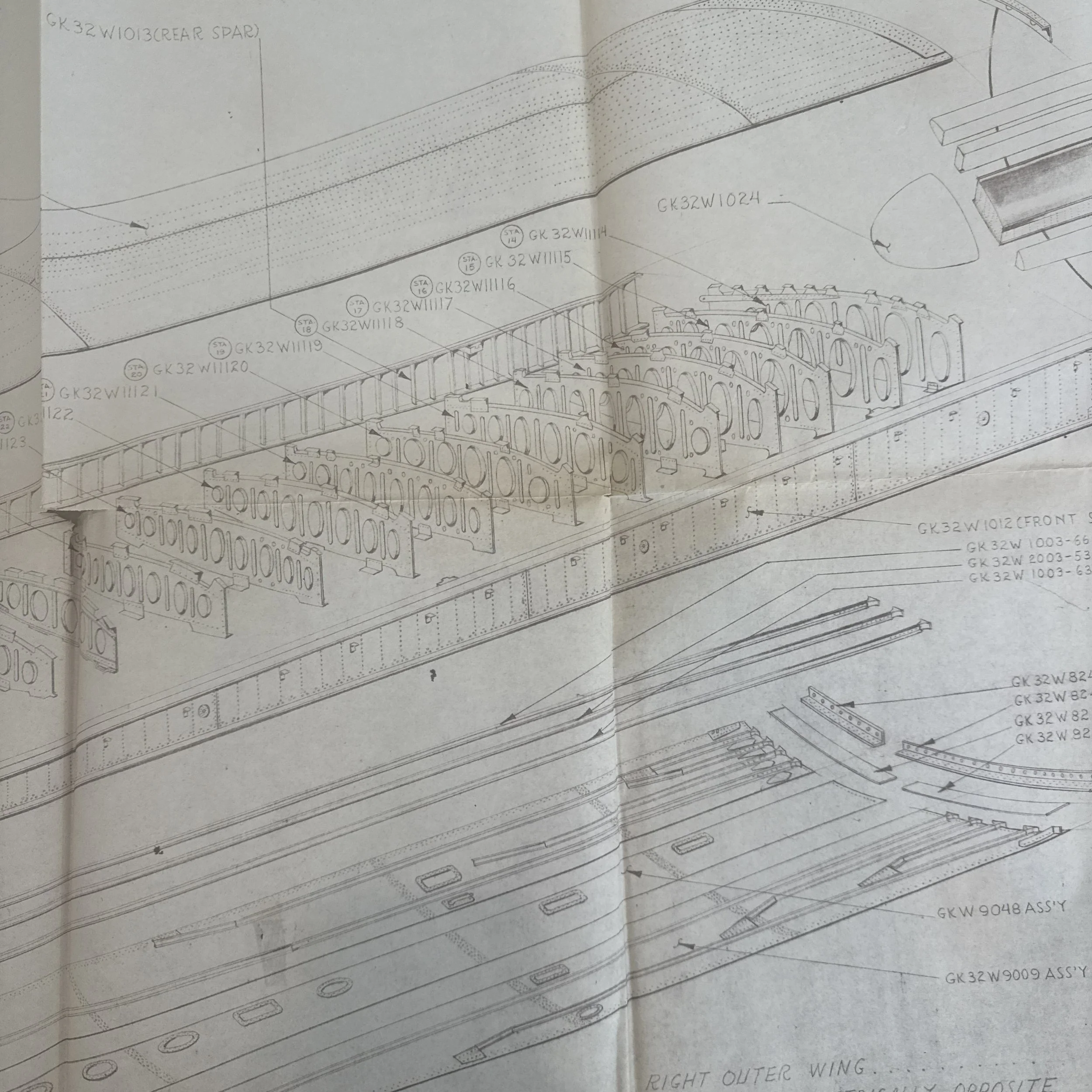

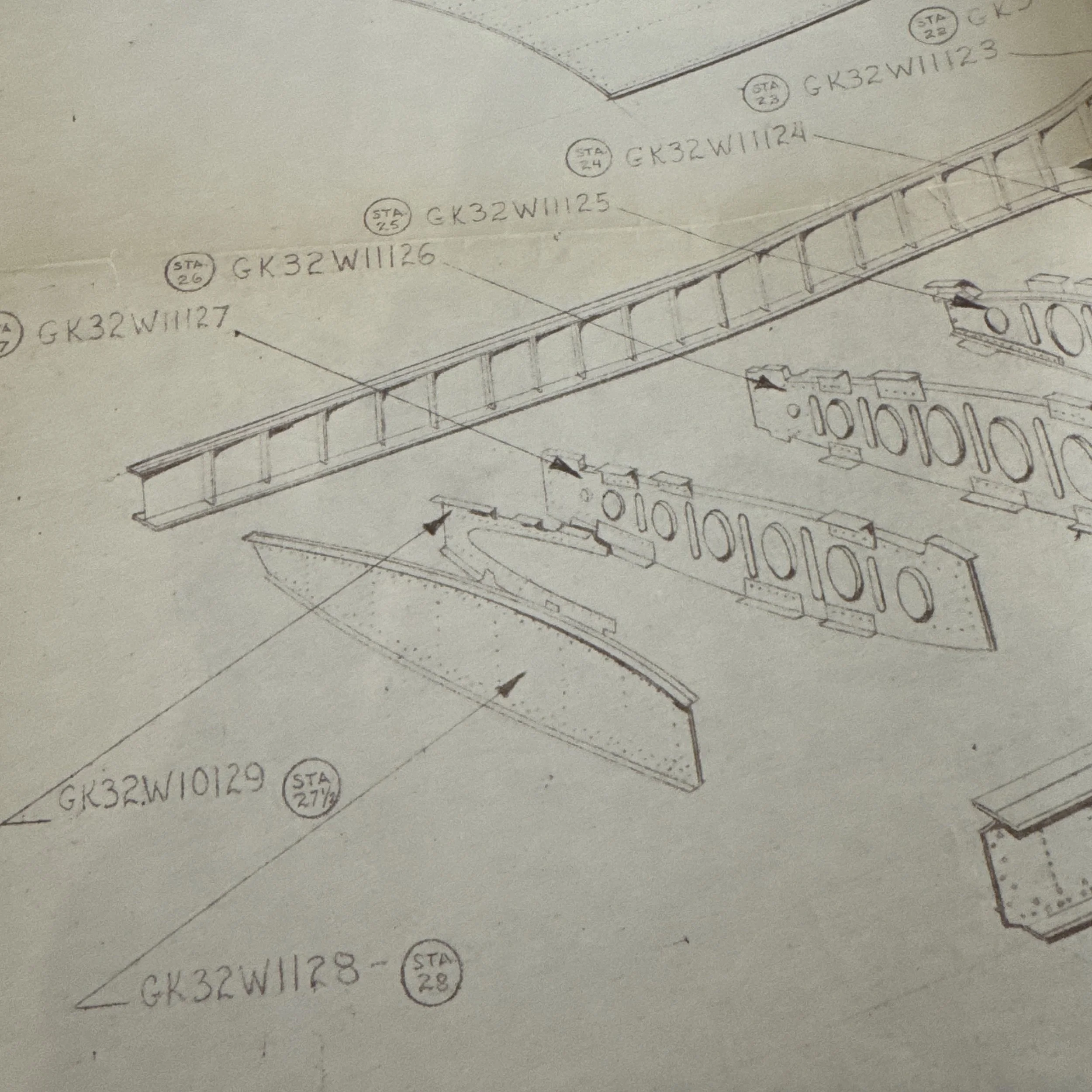

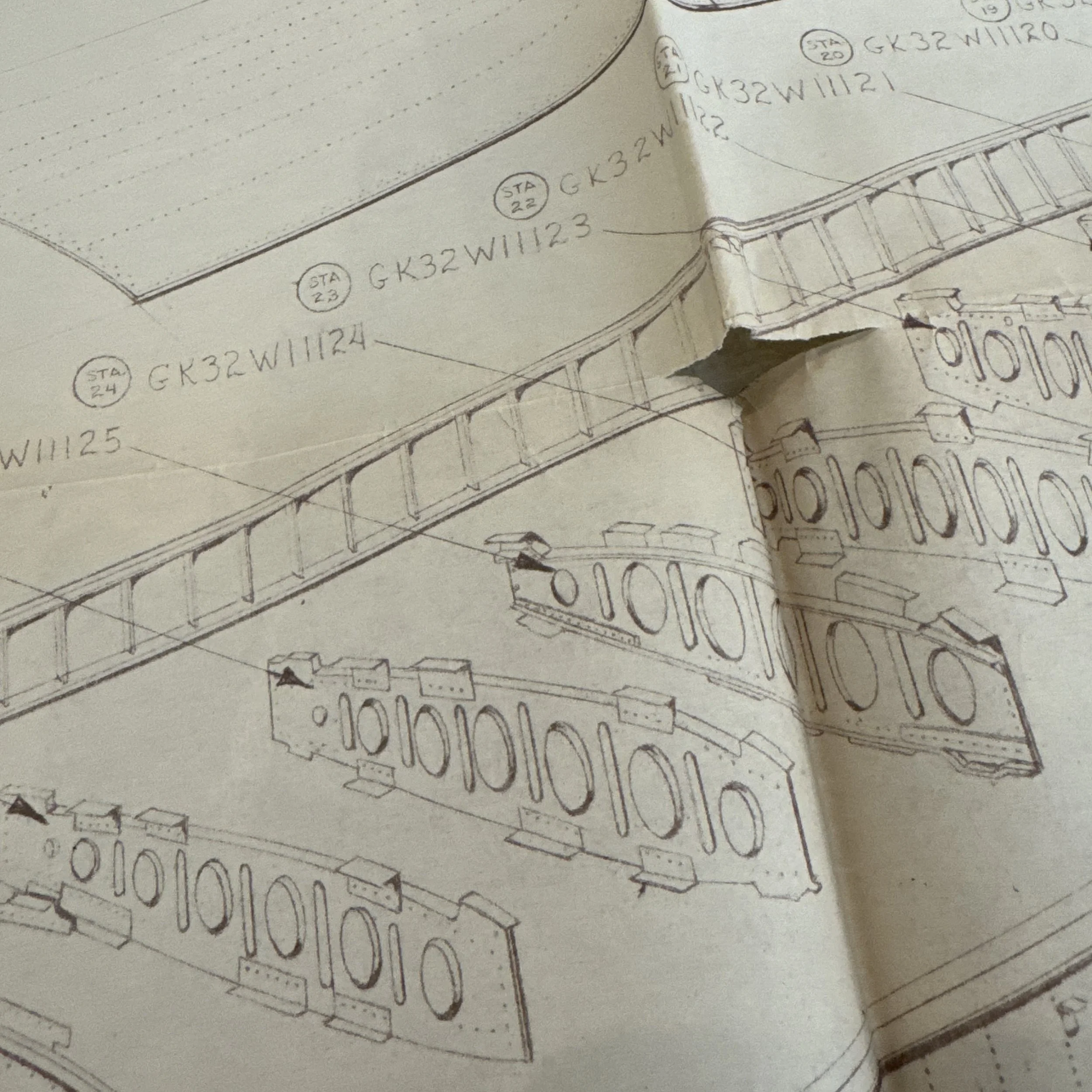

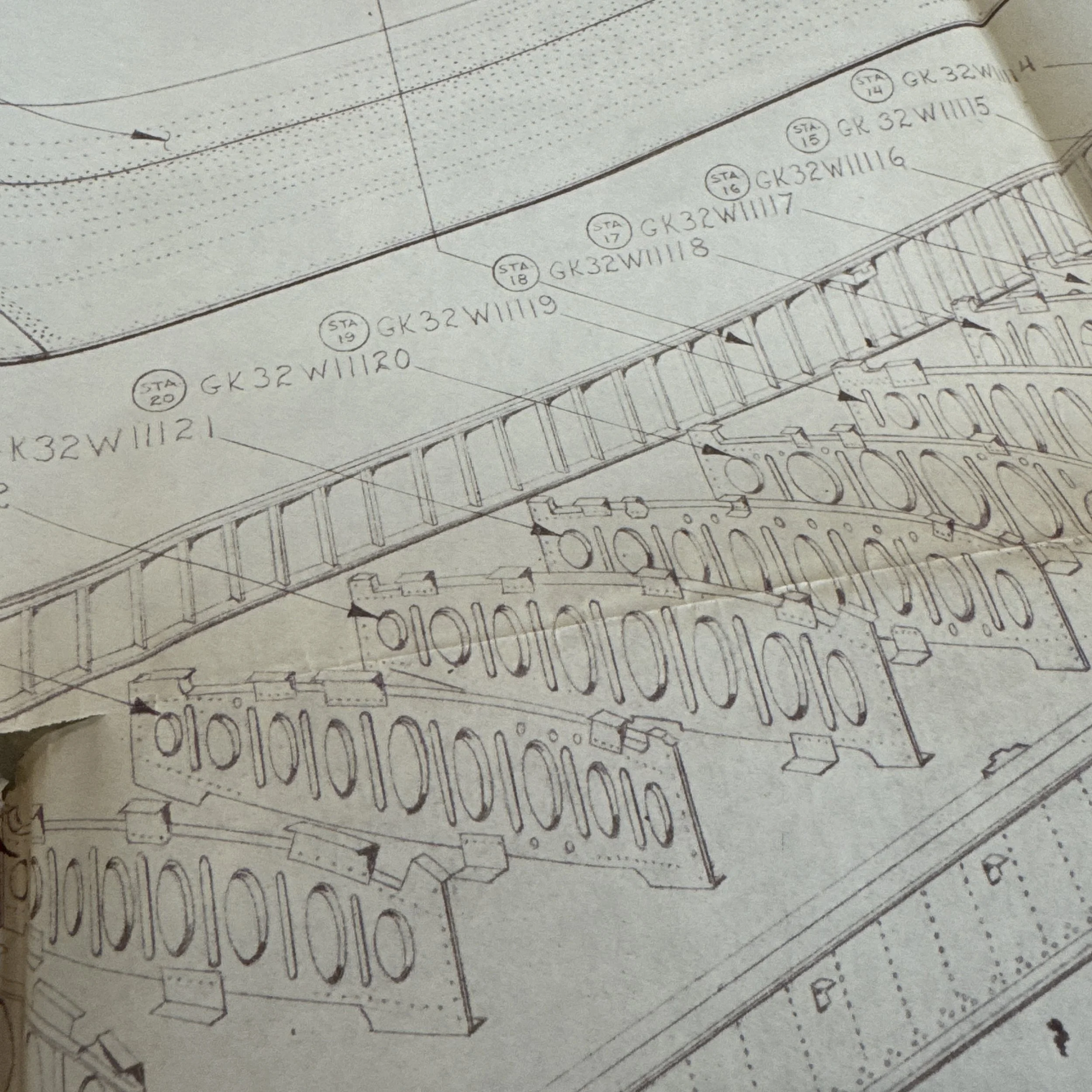

VERY RARE! WWII December 1943 U.S. Army B-24 Liberator Ford Motor Company " Outer Wing Section" Engineering Aircraft Blueprint

VERY RARE! WWII December 1943 U.S. Army B-24 Liberator Ford Motor Company " Outer Wing Section" Engineering Aircraft Blueprint

Comes with a hand-signed C.O.A.

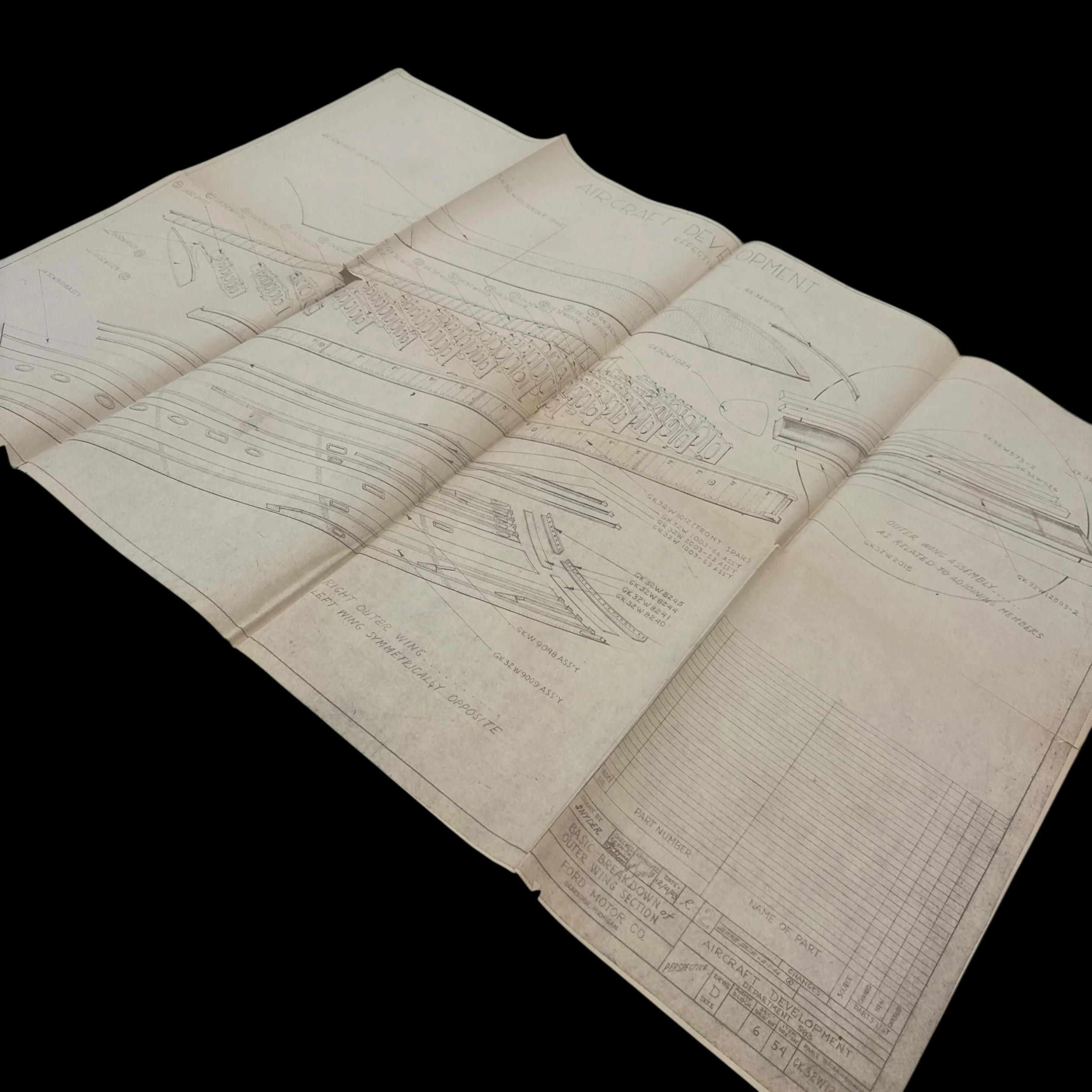

Size: 24 × 35 inches

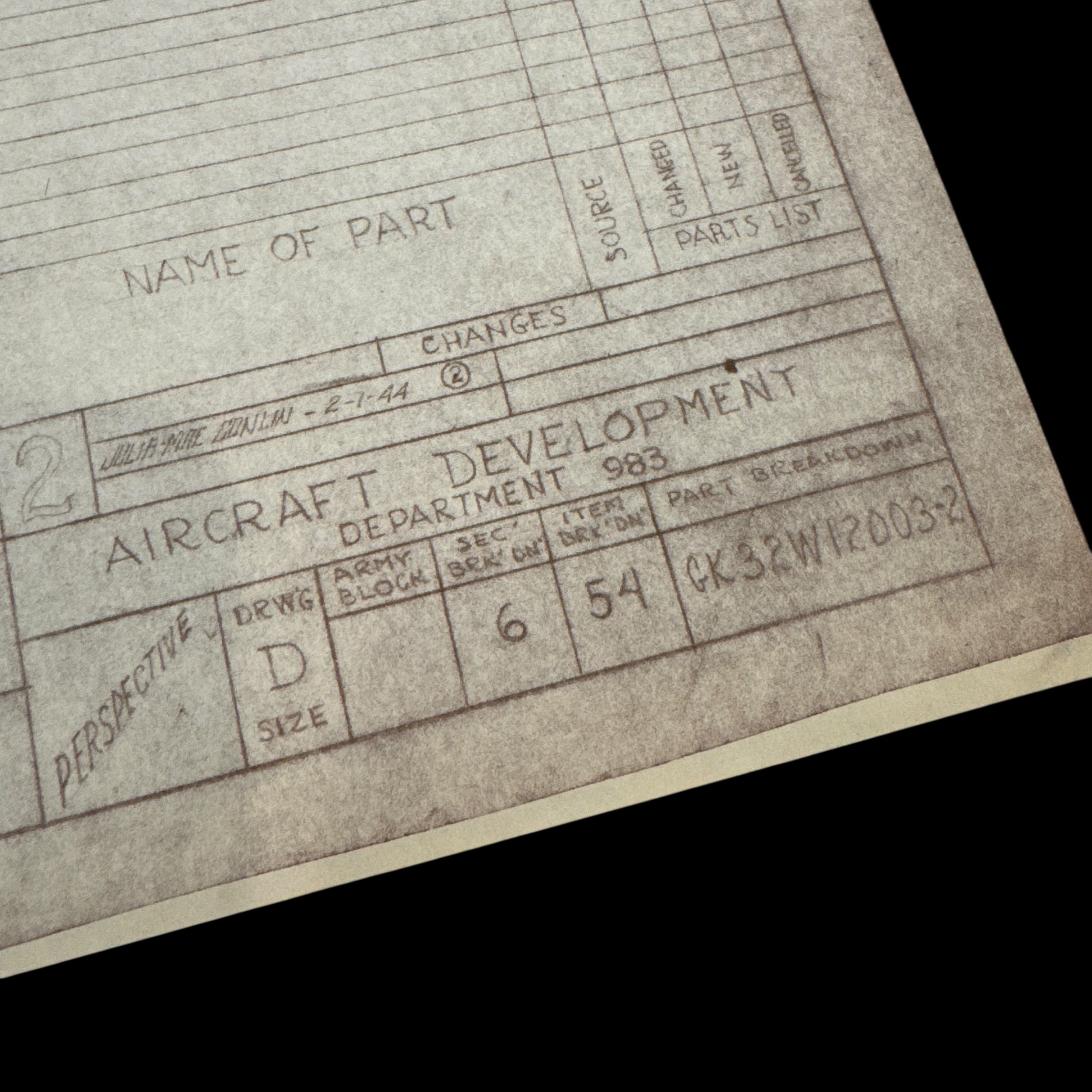

Dated: December 4th, 1943

From: Ford Motor Company

Aircraft: B-24 Liberator

Reason for 1943 Blueprint Revision of the B 24 Liberator Outer Wing Section Construction (A Wartime Advancement in Structural Strength and Mass Production Efficiency):

The 1943 revision of the B 24 Liberator outer wing section construction reflected the urgent need to improve both structural reliability and manufacturing speed as combat operations expanded across Europe and the Pacific. Earlier wing designs required more complex assembly methods and additional reinforcement parts, which increased production time and material use while also introducing more potential stress points under combat loads. This updated blueprint simplified the internal breakdown of the wing by refining spar placement, rib alignment, and skin panel integration, creating a stronger and more uniform structure that could better withstand heavy bomb loads, long range flight, and battle damage. The revised design reduced unnecessary complexity by standardizing components and improving how sections of the wing fit together on the assembly line. This allowed factory workers to build wings faster with greater consistency and fewer errors. Fewer parts meant less weight and fewer failure points. Every improvement in wing construction translated directly into better lift performance, improved fuel efficiency, and increased aircraft durability during extended missions over enemy territory. For aircrews, the strengthened and more precisely engineered outer wing sections improved overall aircraft stability and survivability. The wings housed critical systems such as fuel tanks and control surfaces, so enhancing their structural layout helped protect these systems from vibration, fatigue, and combat stress. This made the aircraft safer to fly and more dependable in harsh operational conditions.

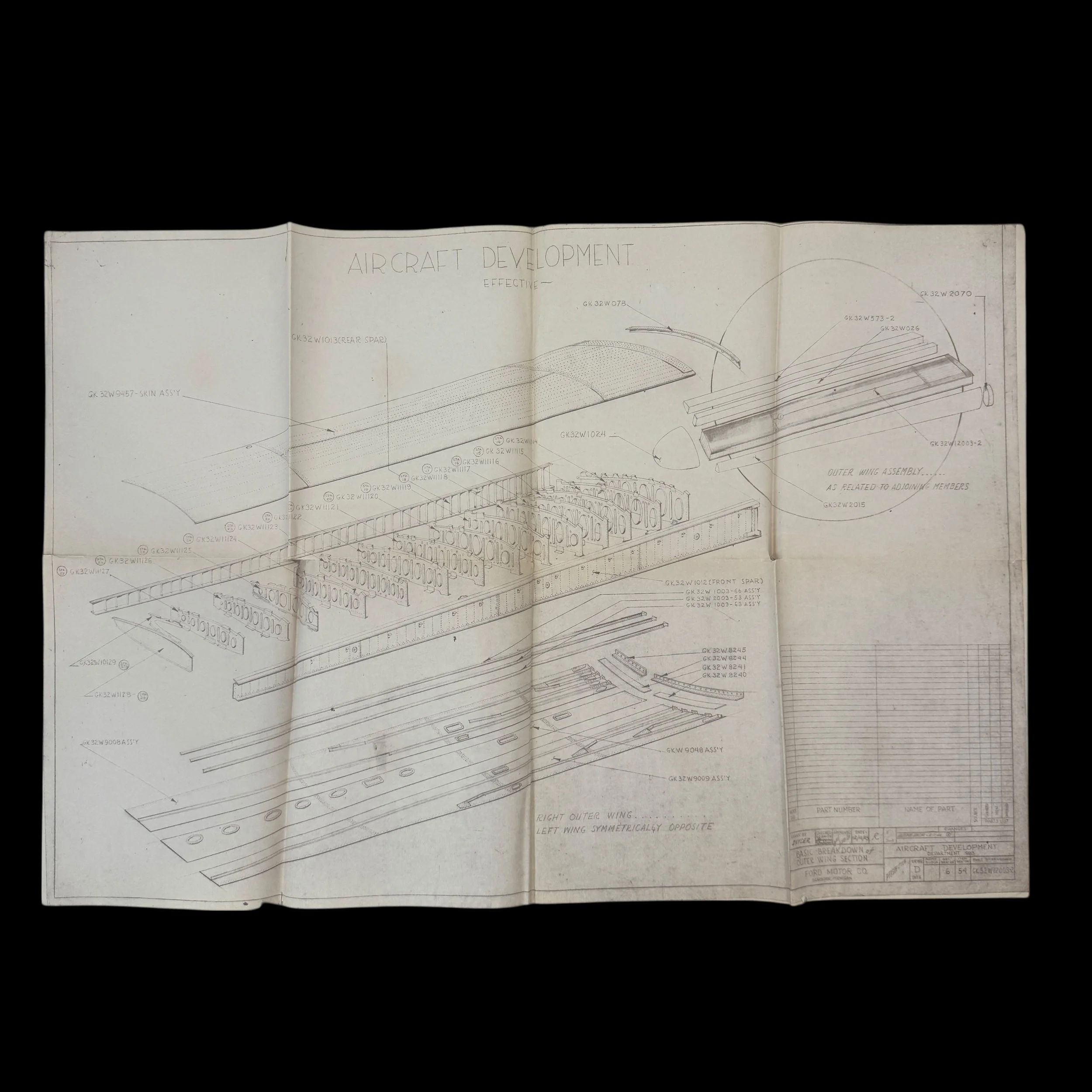

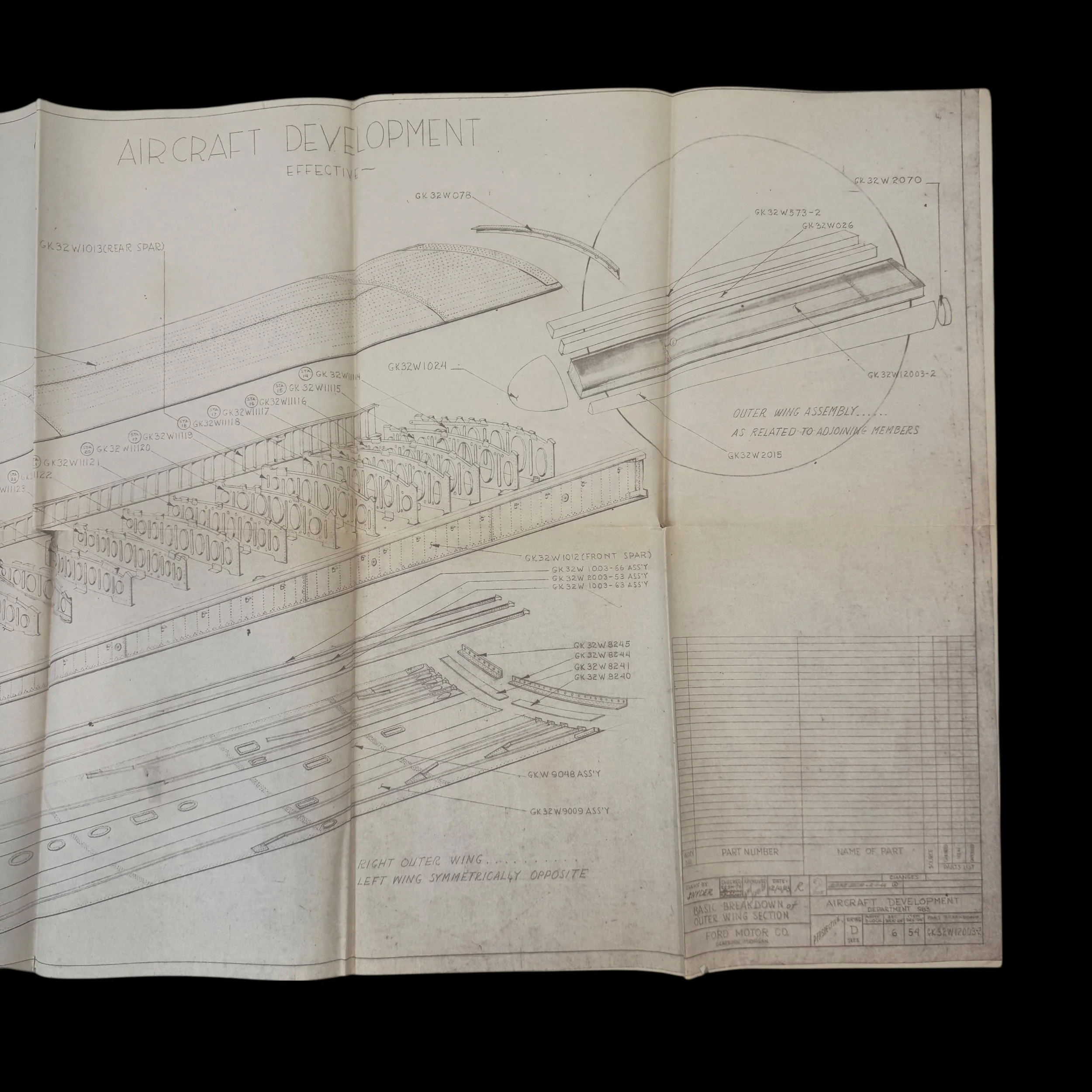

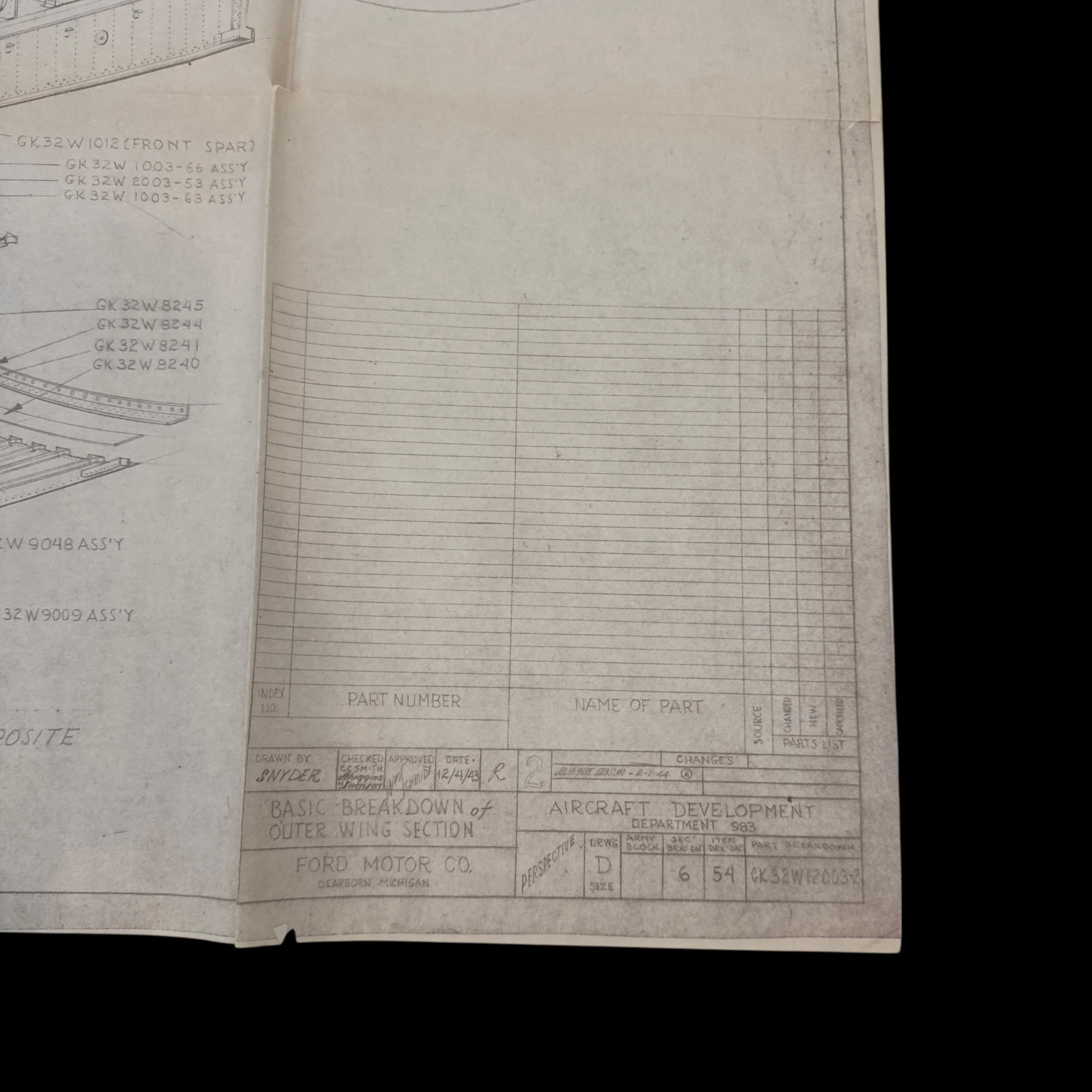

This extraordinary and museum grade World War II artifact is an original Ford Motor Company engineering blueprint dated December 4th, 1943, created during the peak of America’s wartime aircraft production effort for the legendary B 24 Liberator bomber. This document is not a reproduction or a later technical schematic. It is a true wartime engineering illustration produced for active use in the design, construction, and refinement of one of the most important heavy bombers of the Second World War.

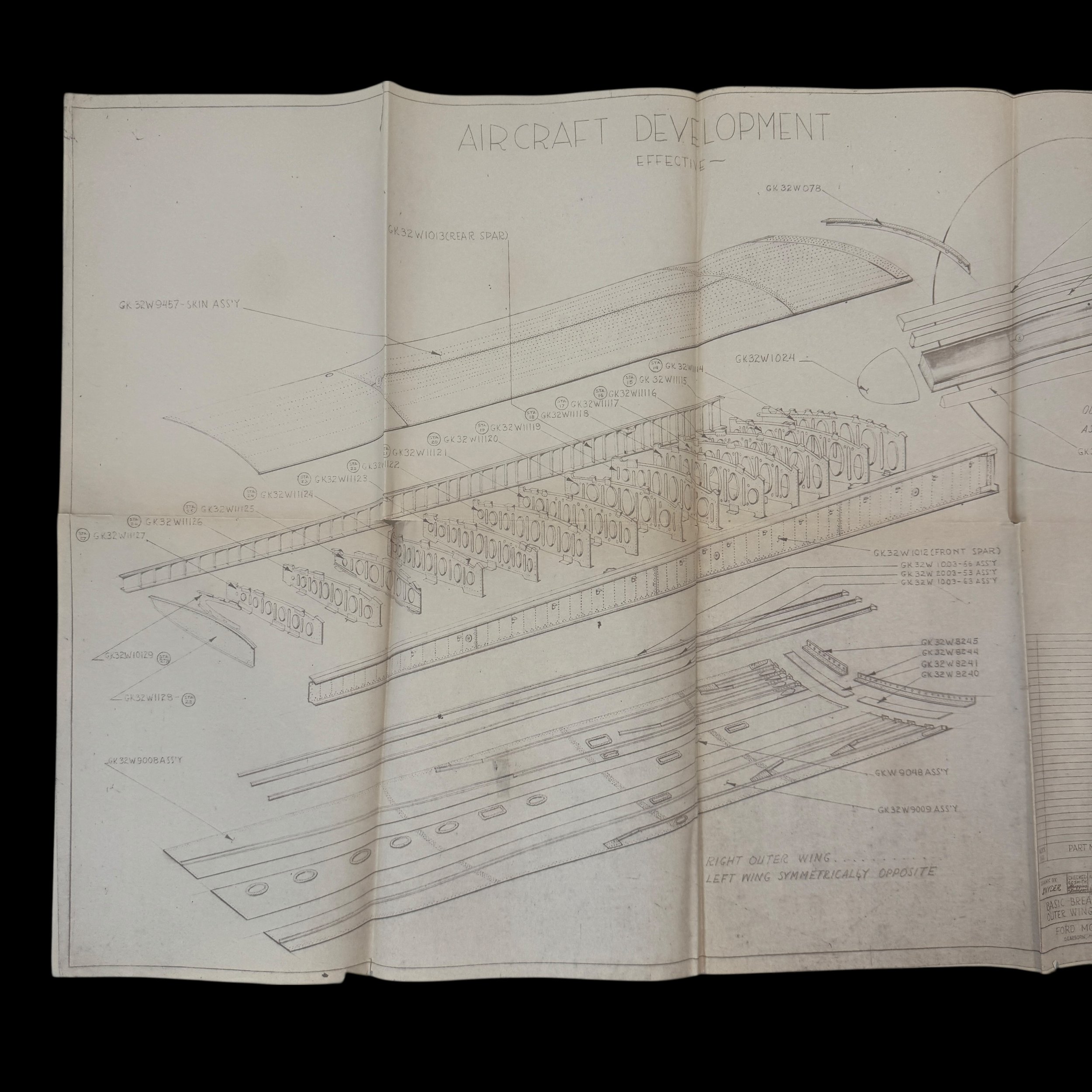

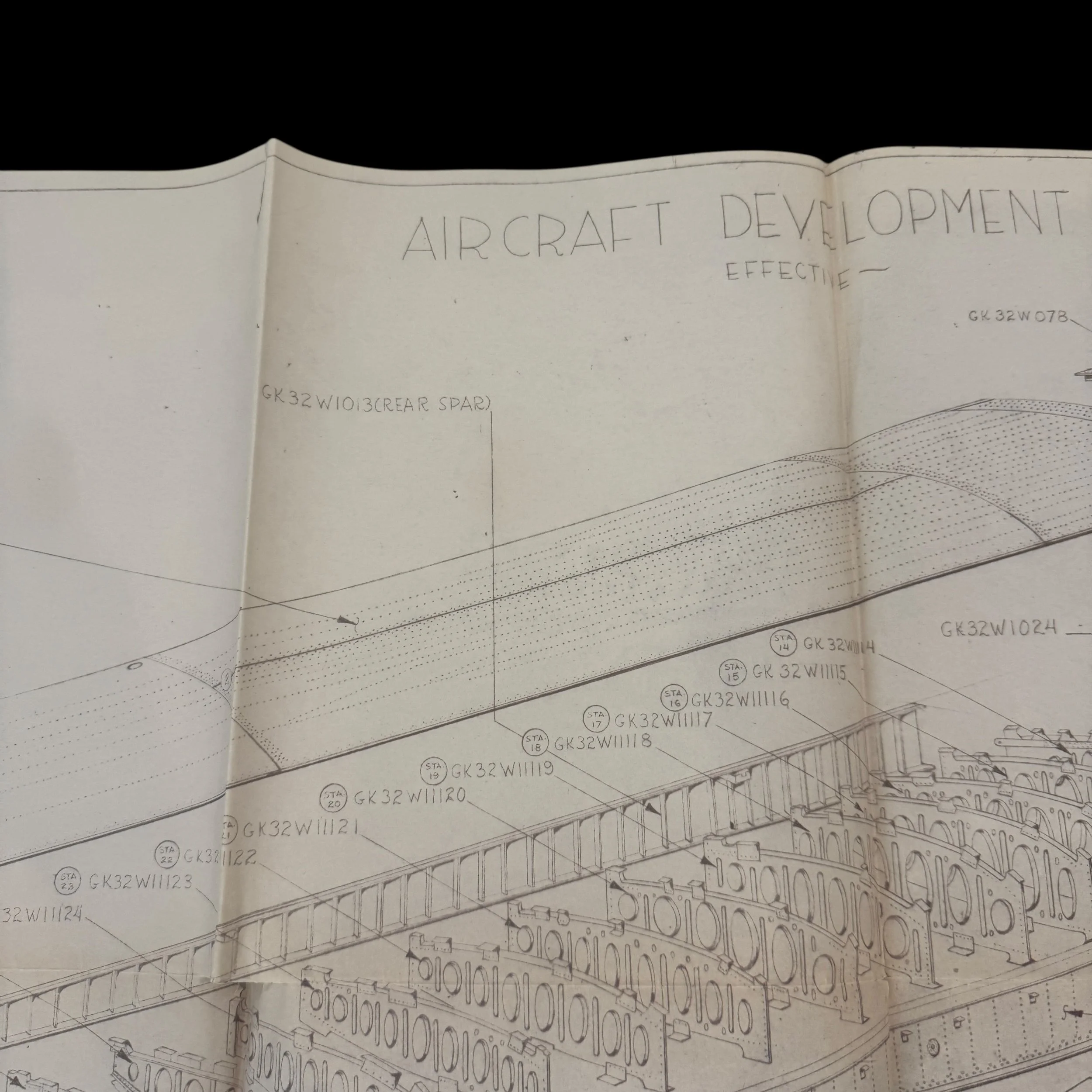

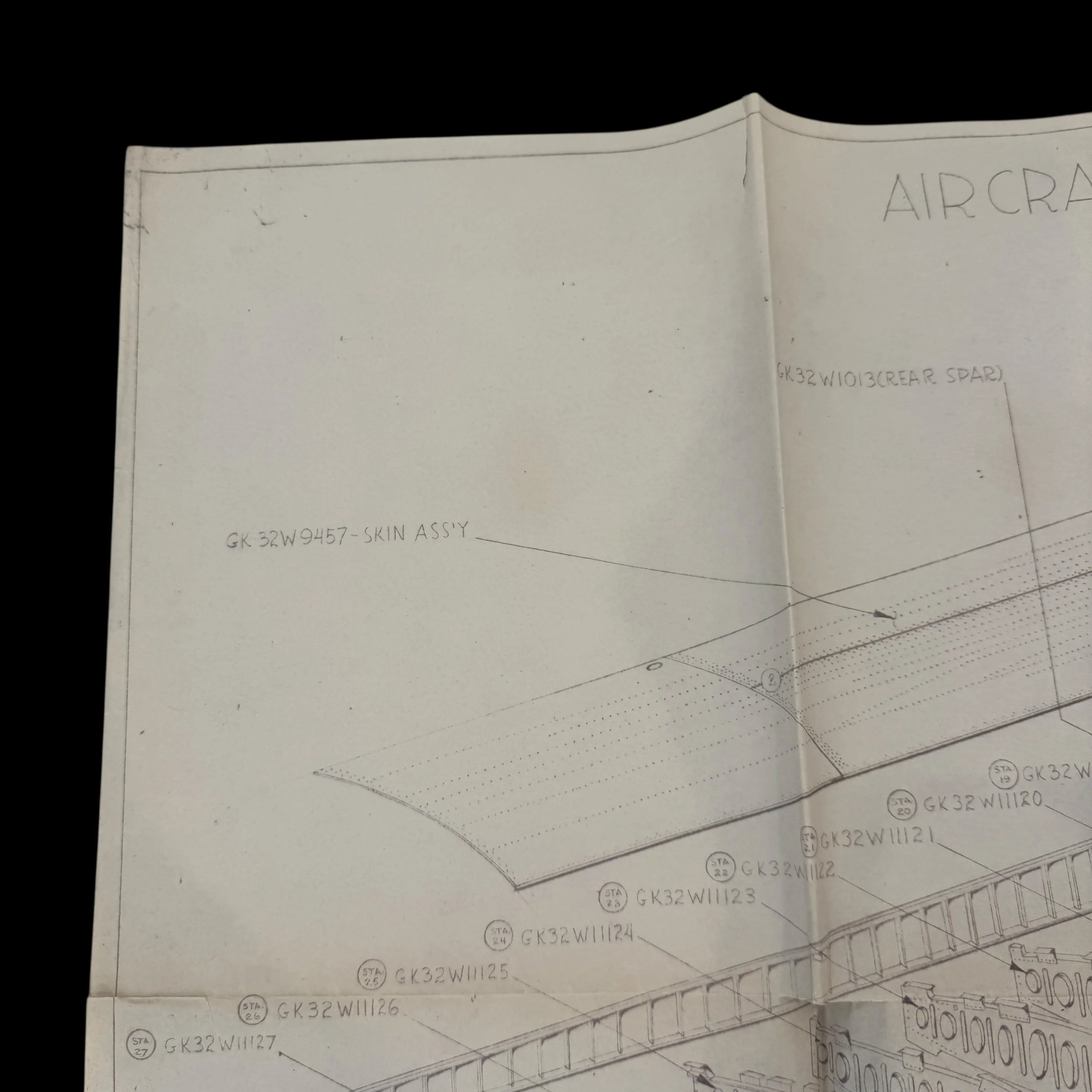

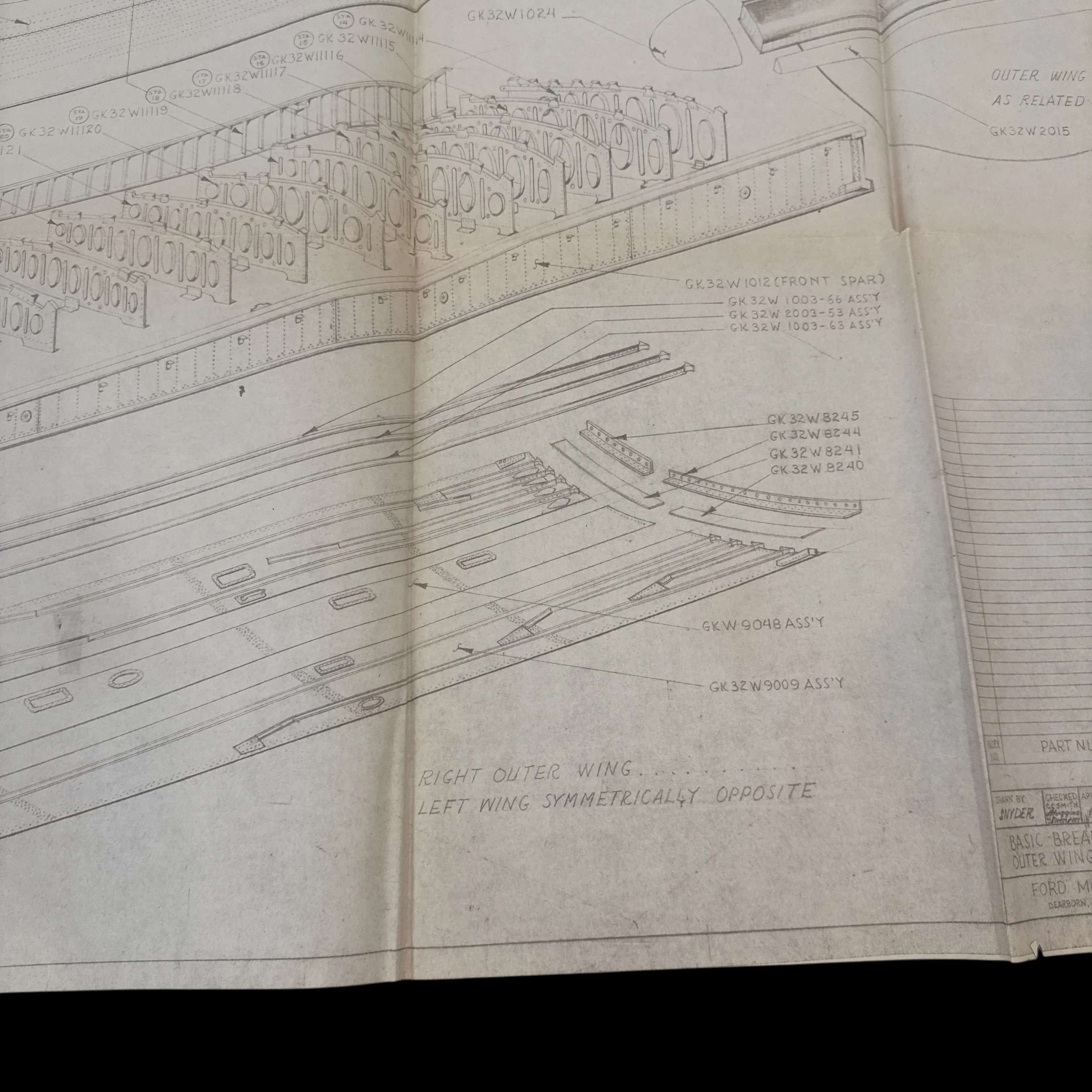

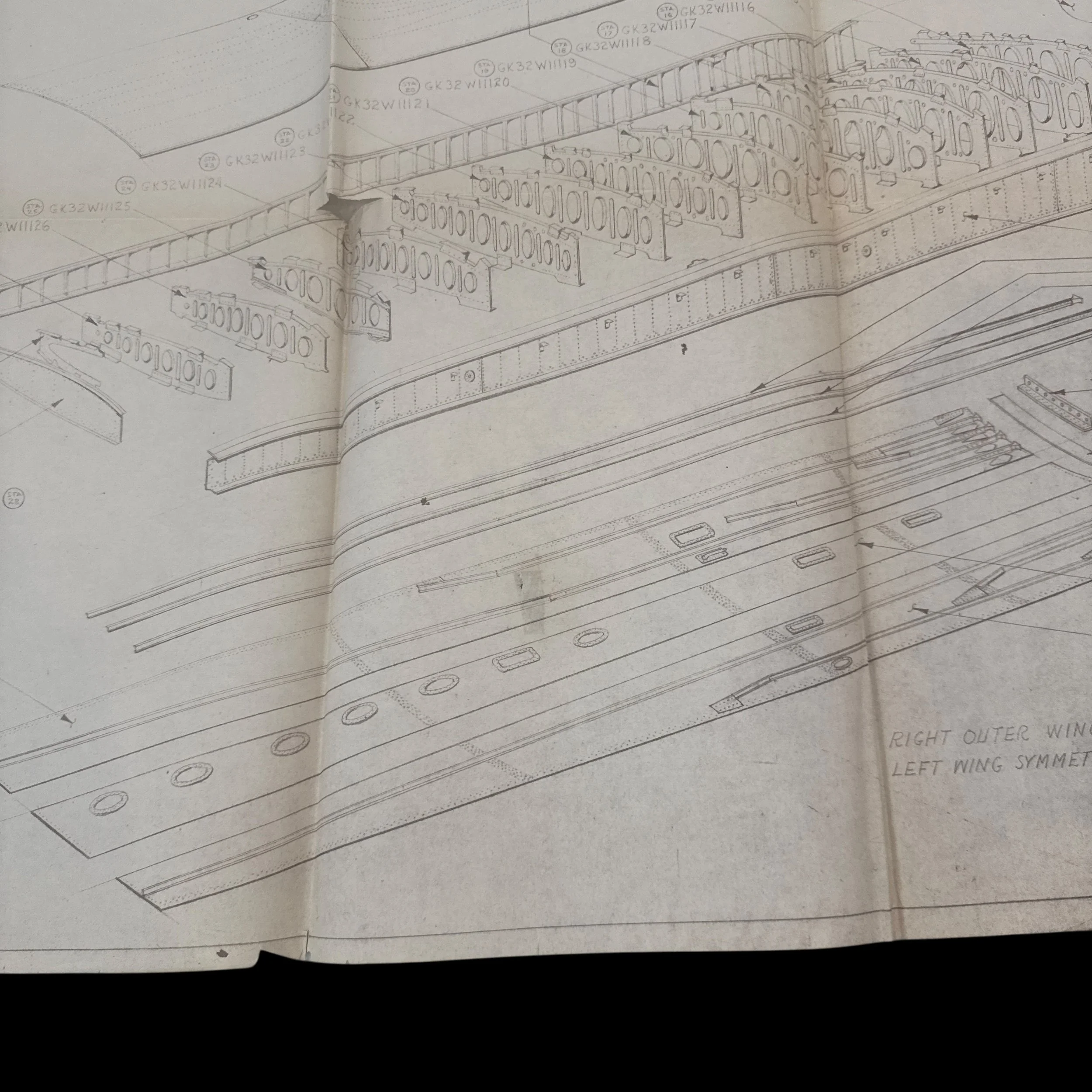

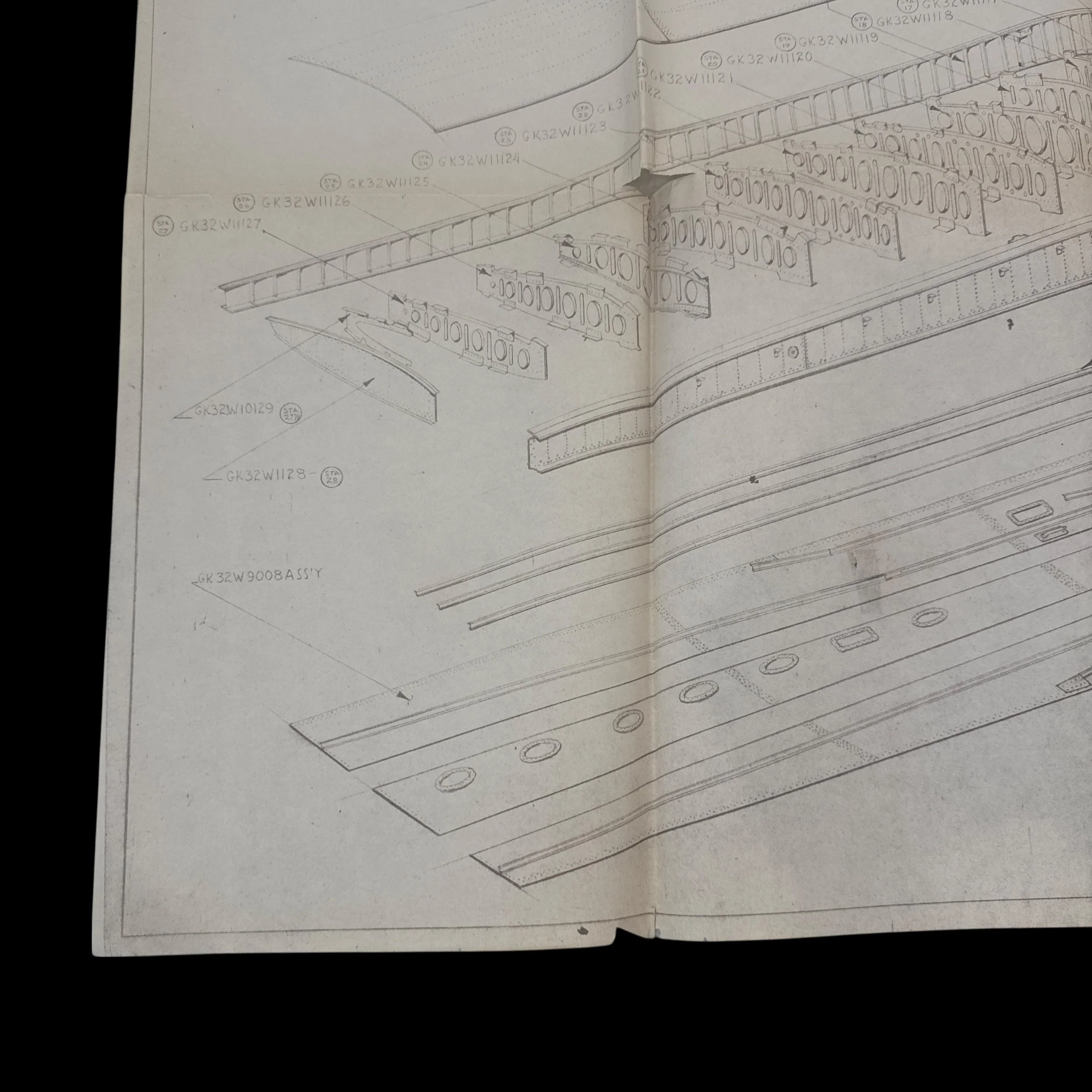

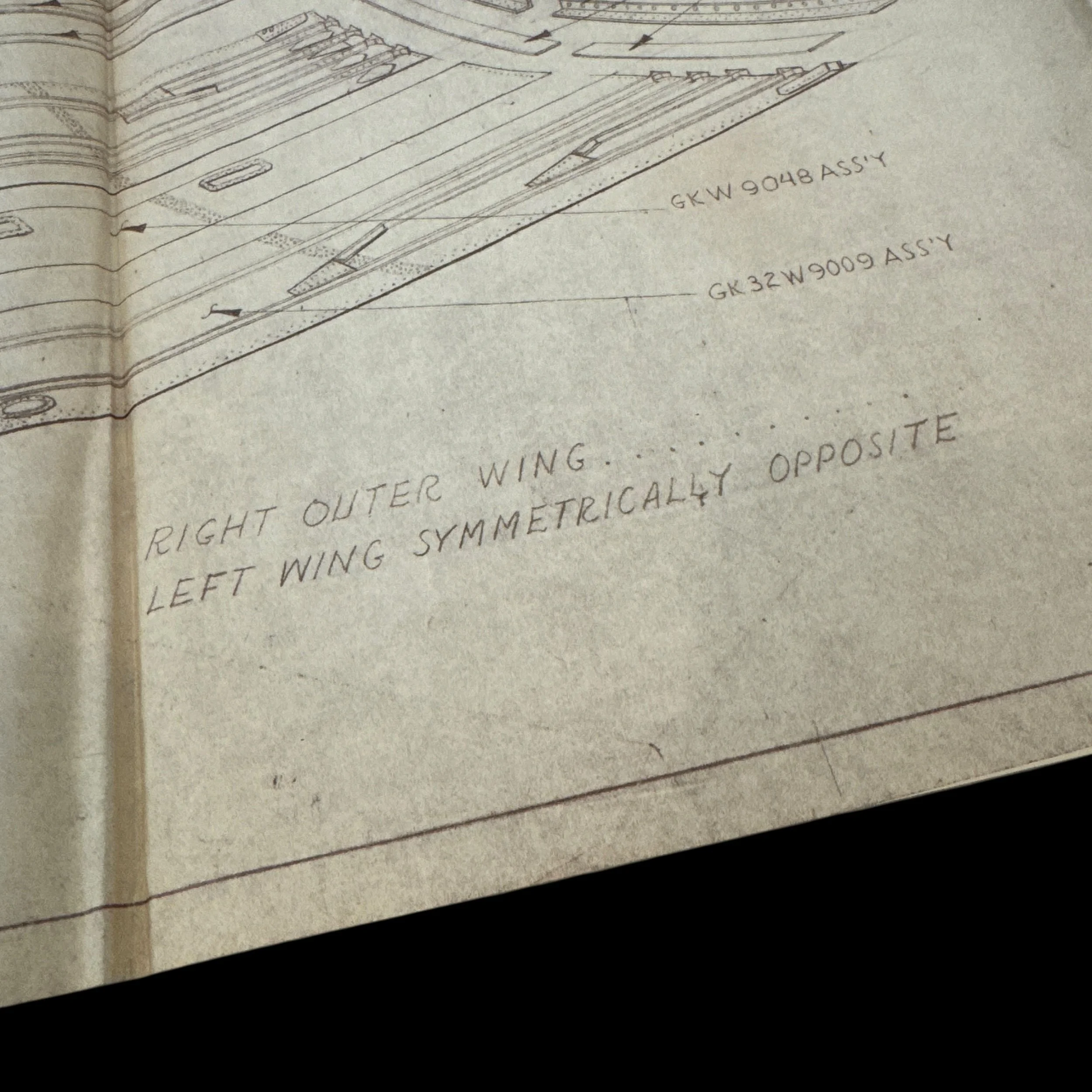

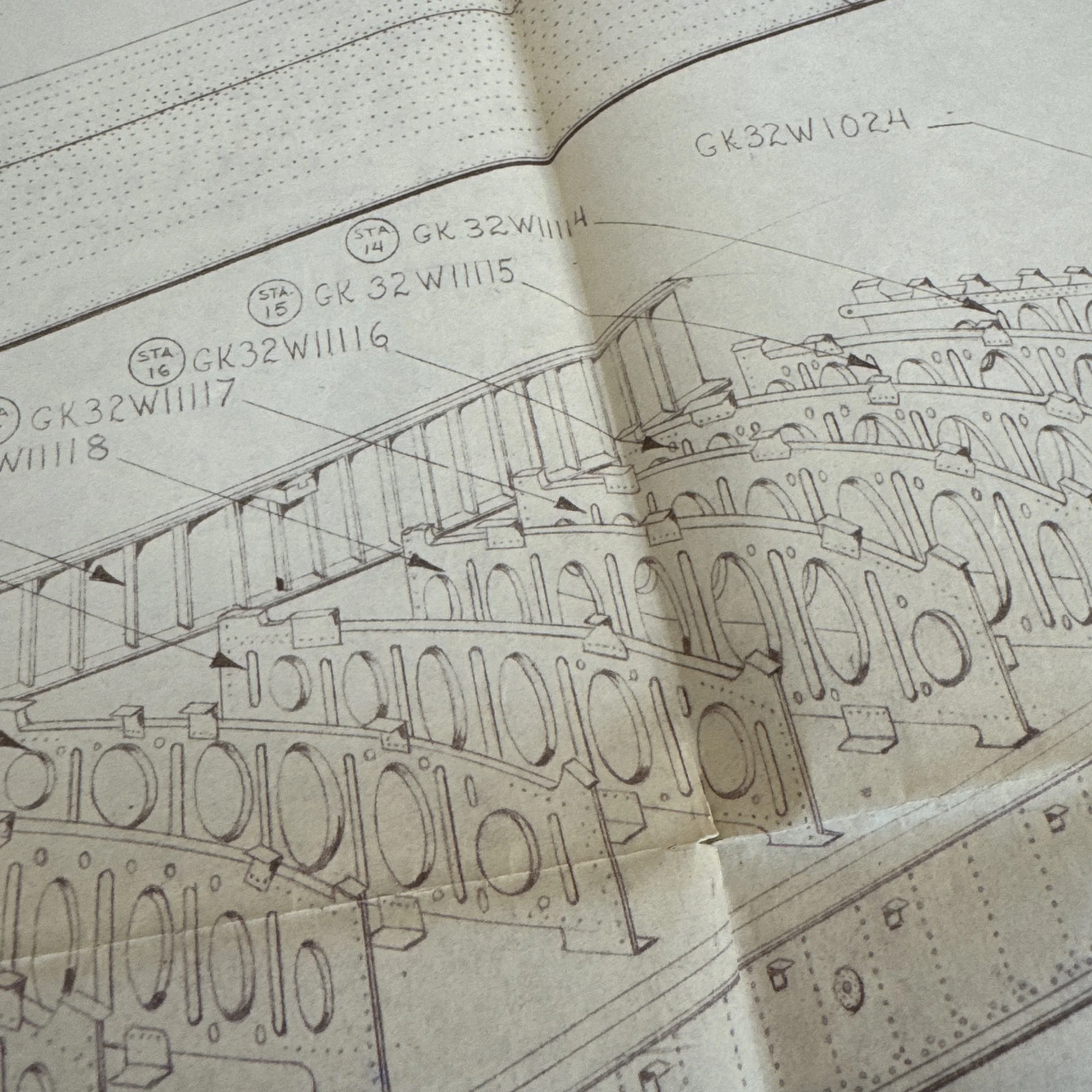

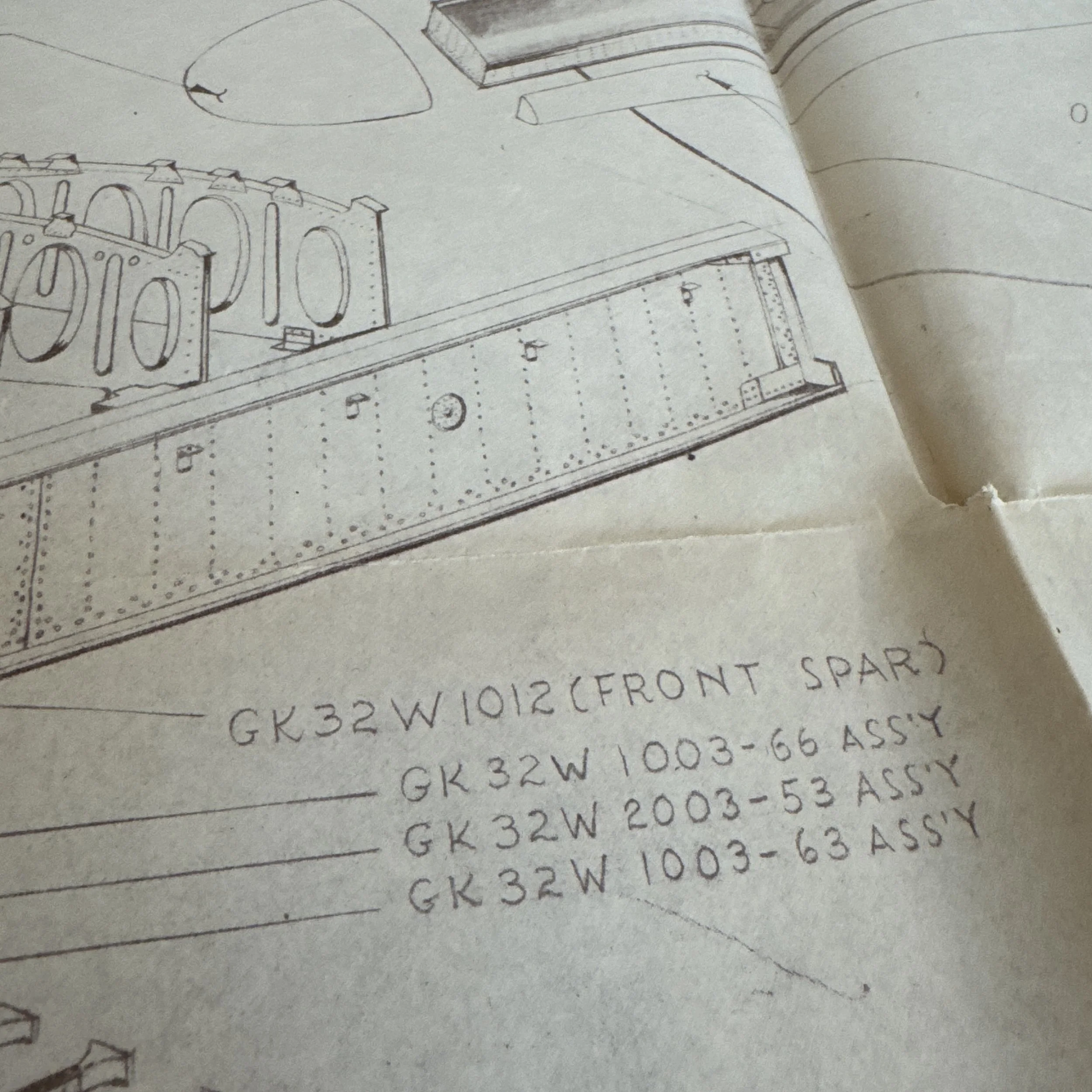

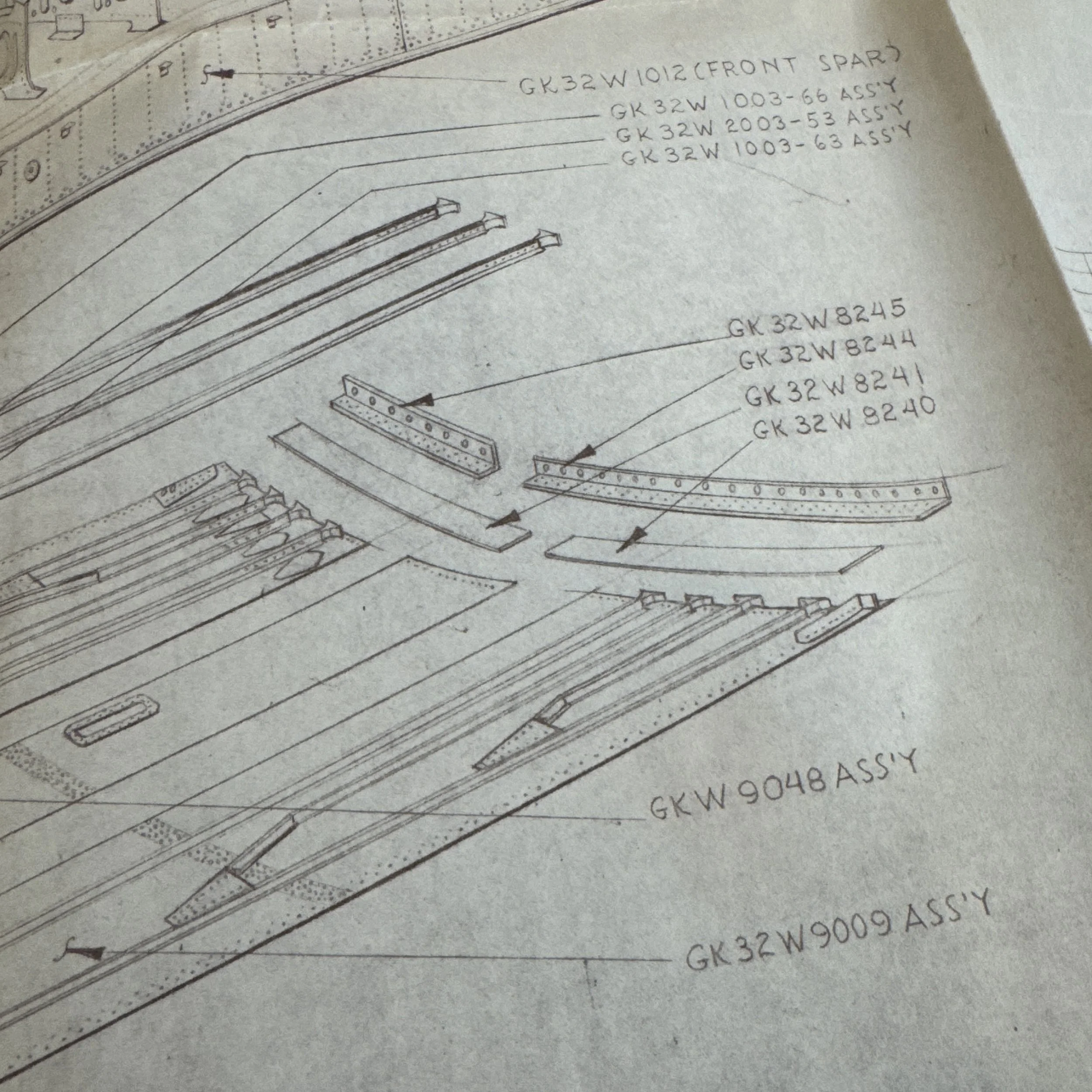

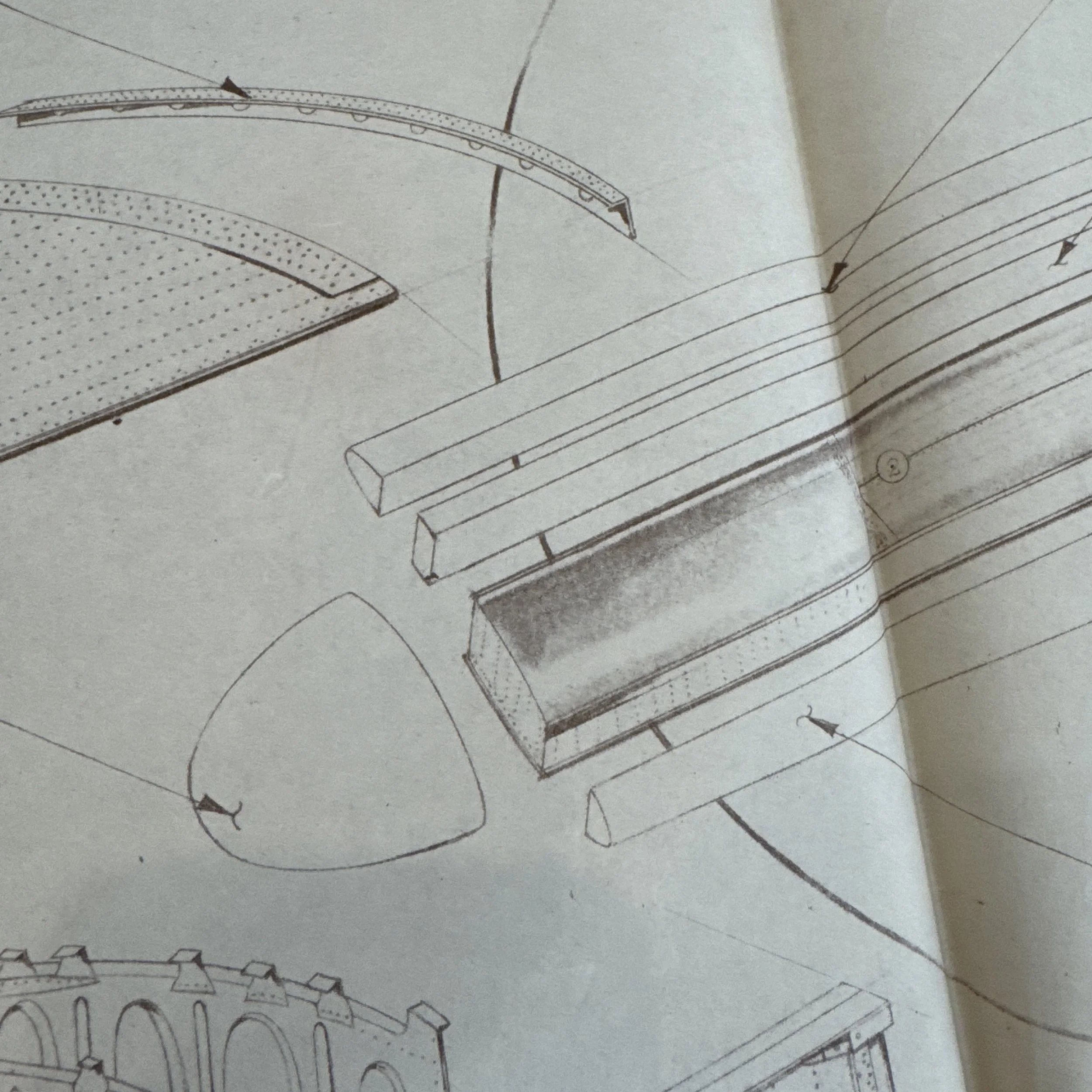

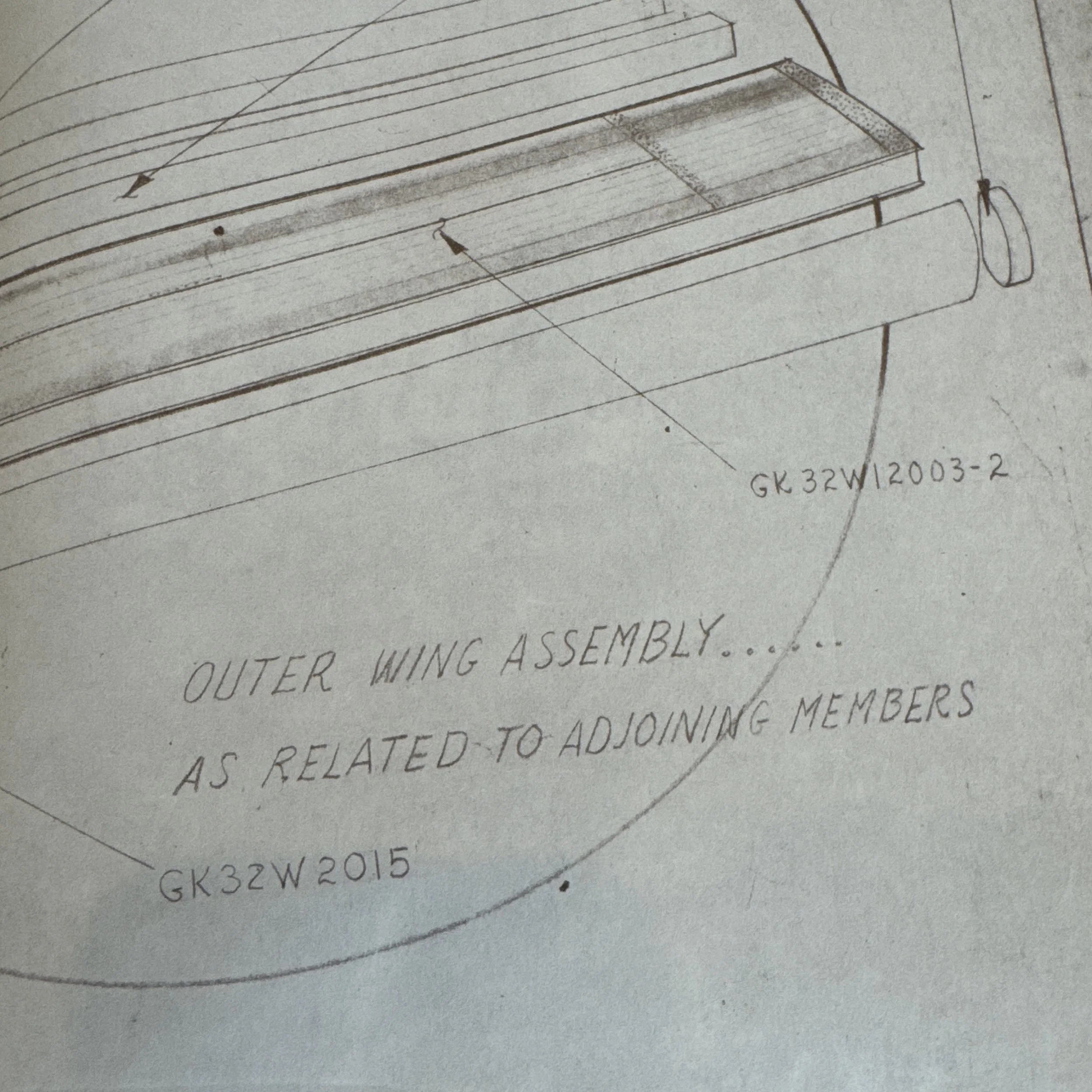

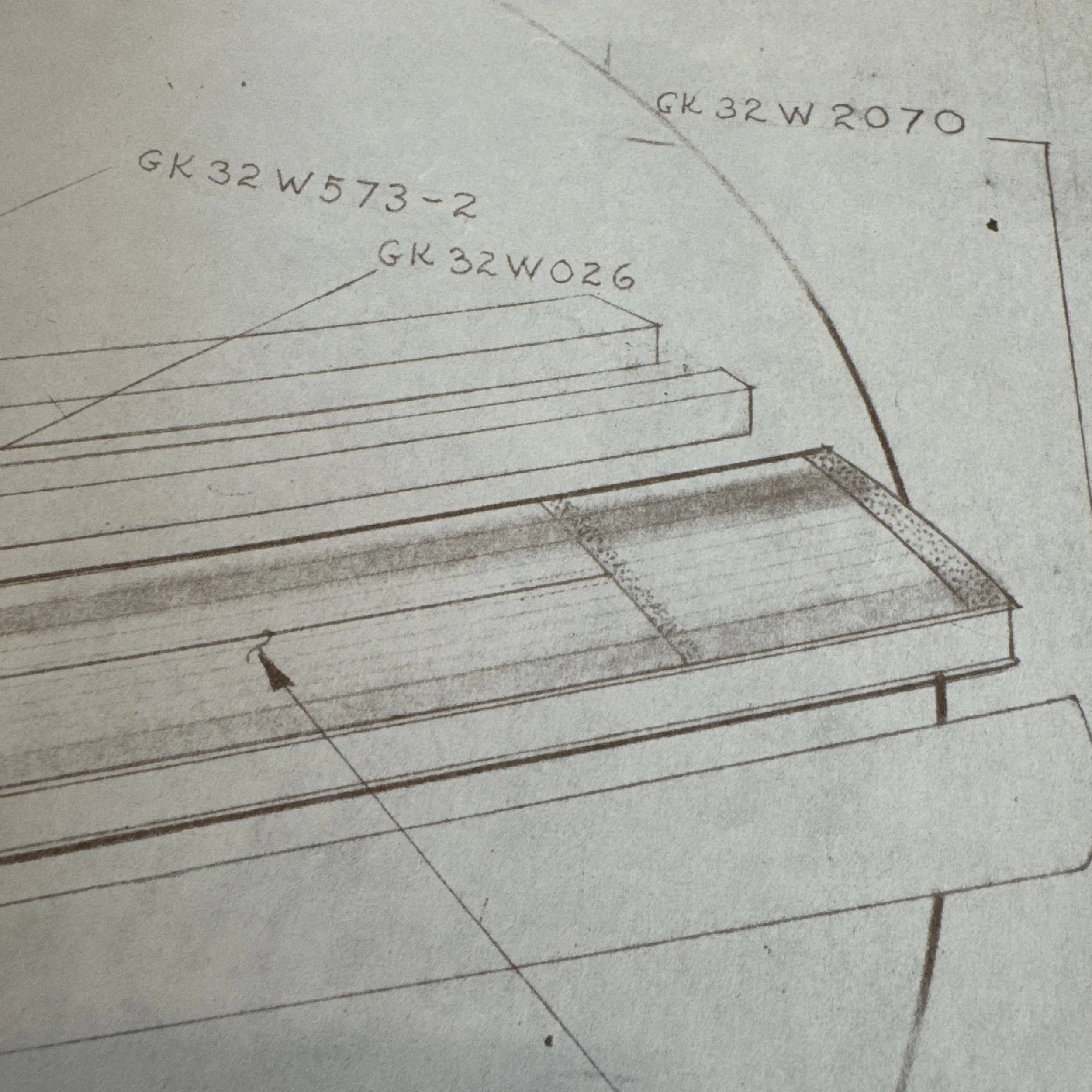

The blueprint represents a one of a kind original revision drawing detailing the basic structural breakdown and outer wing section construction of the U.S. Army Air Forces Consolidated B 24 Liberator. Engineering illustrations such as this were used directly by aircraft engineers and factory production teams to guide the assembly of major airframe components and to implement improvements on the manufacturing floor. This specific drawing reflects an official wartime design standard authorized in late 1943, a period when speed of production, structural strength, and aerodynamic efficiency were essential to sustaining the Allied bombing campaigns across both the European and Pacific theaters.

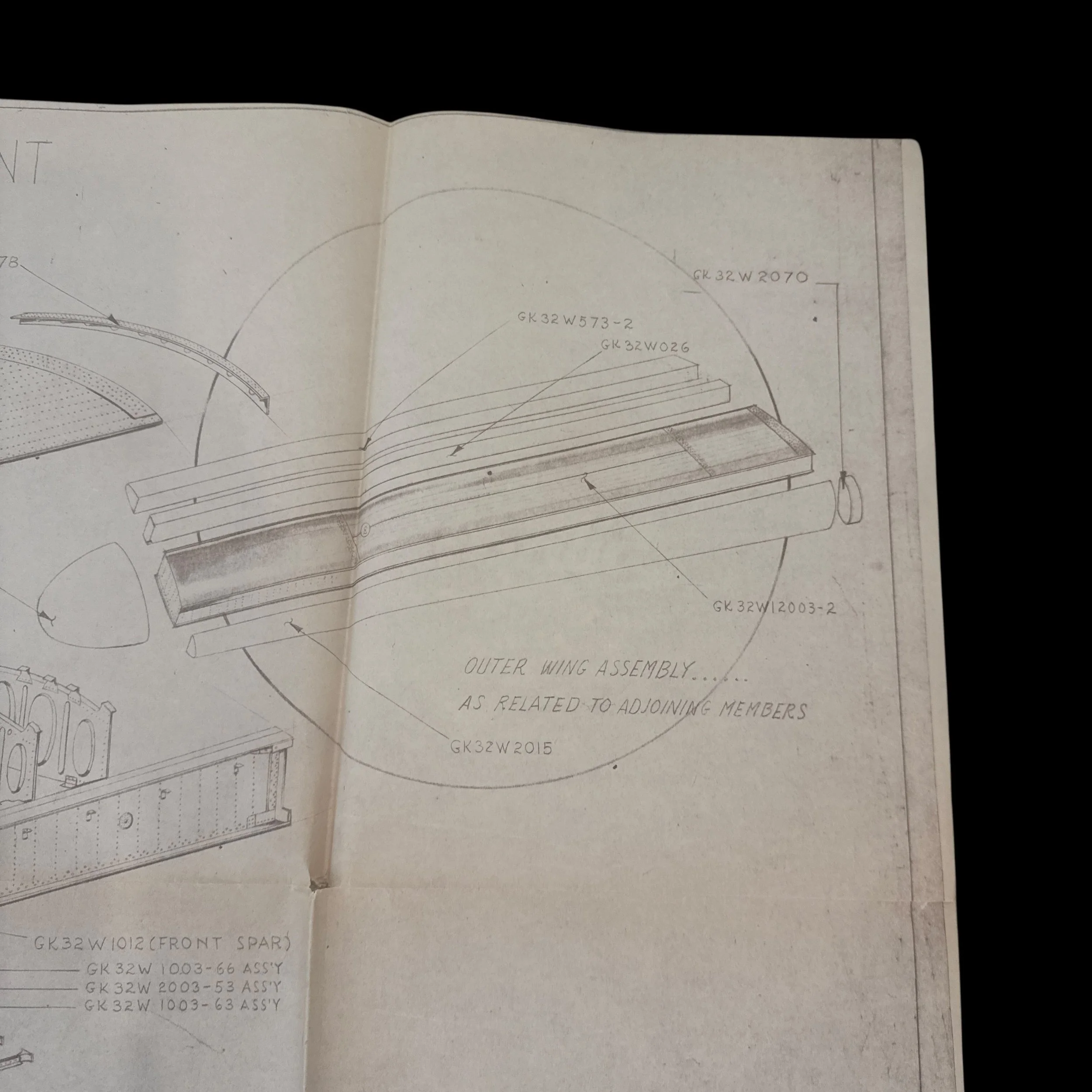

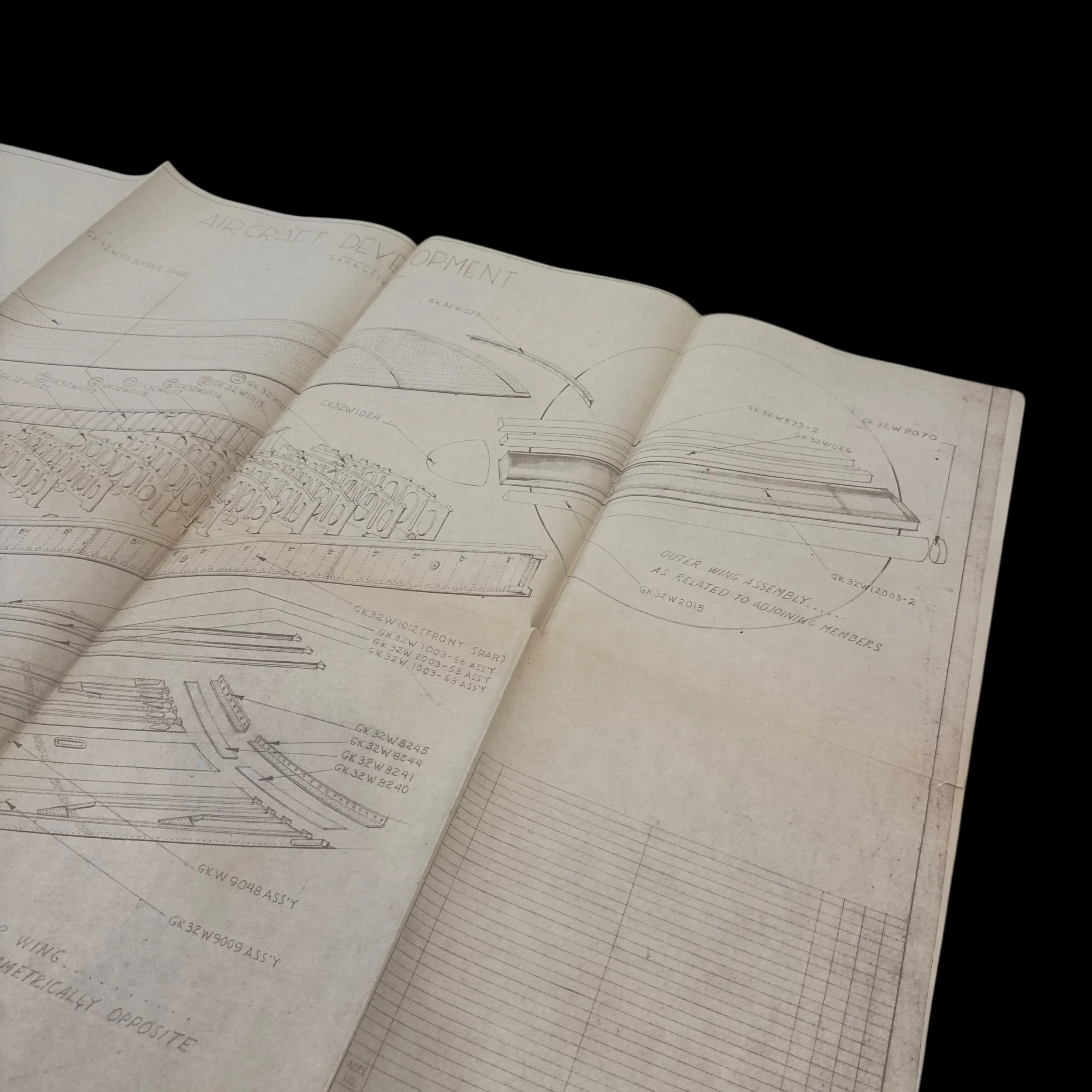

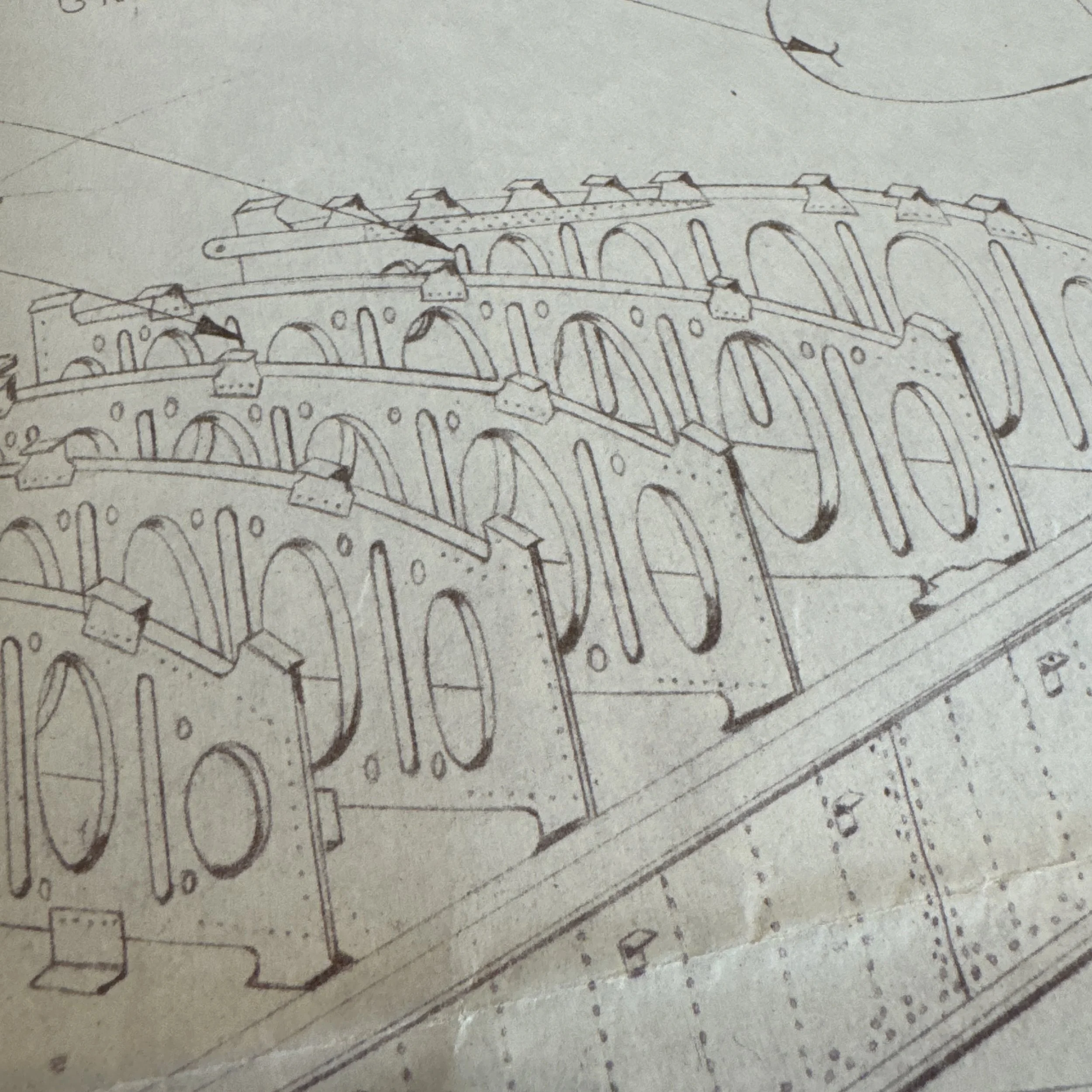

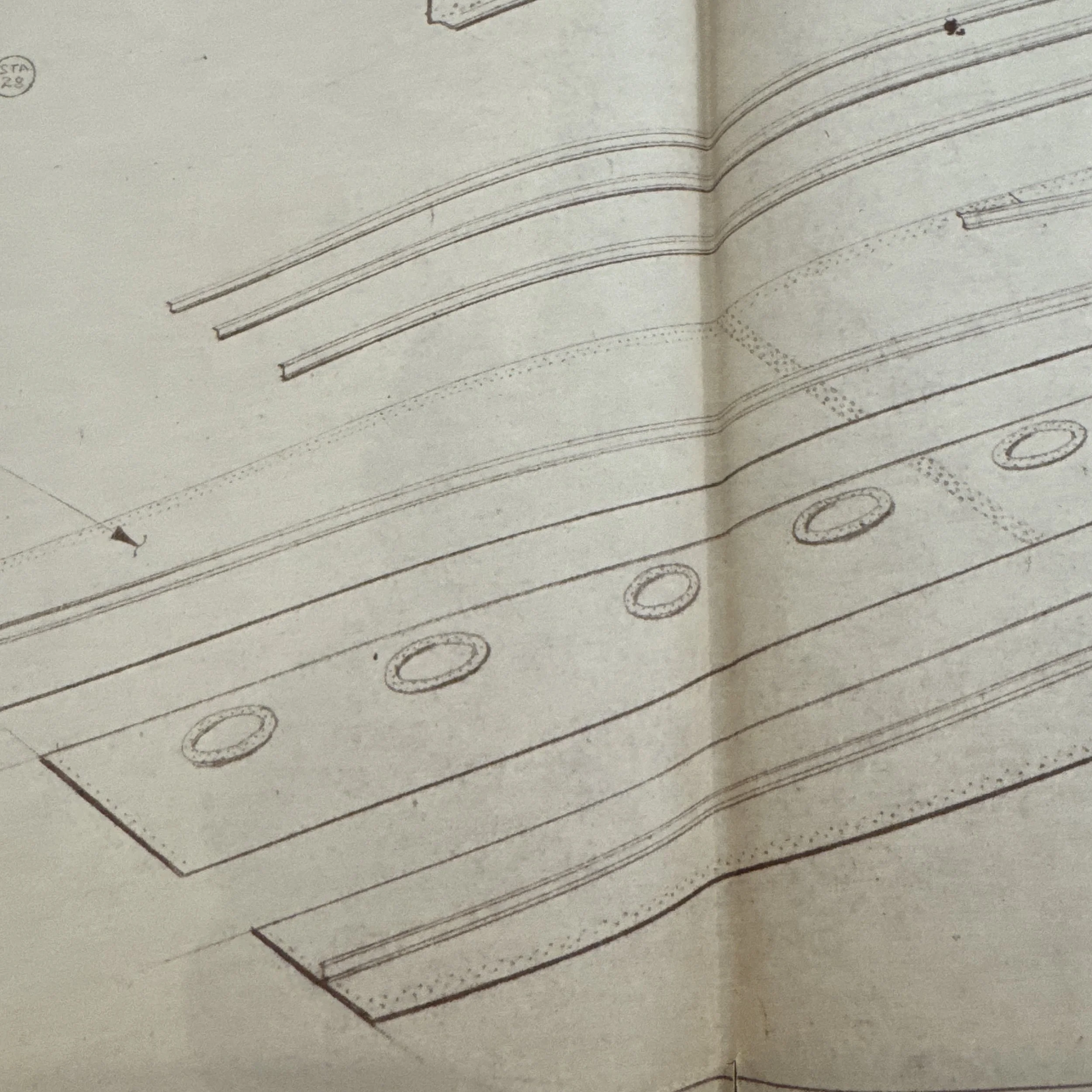

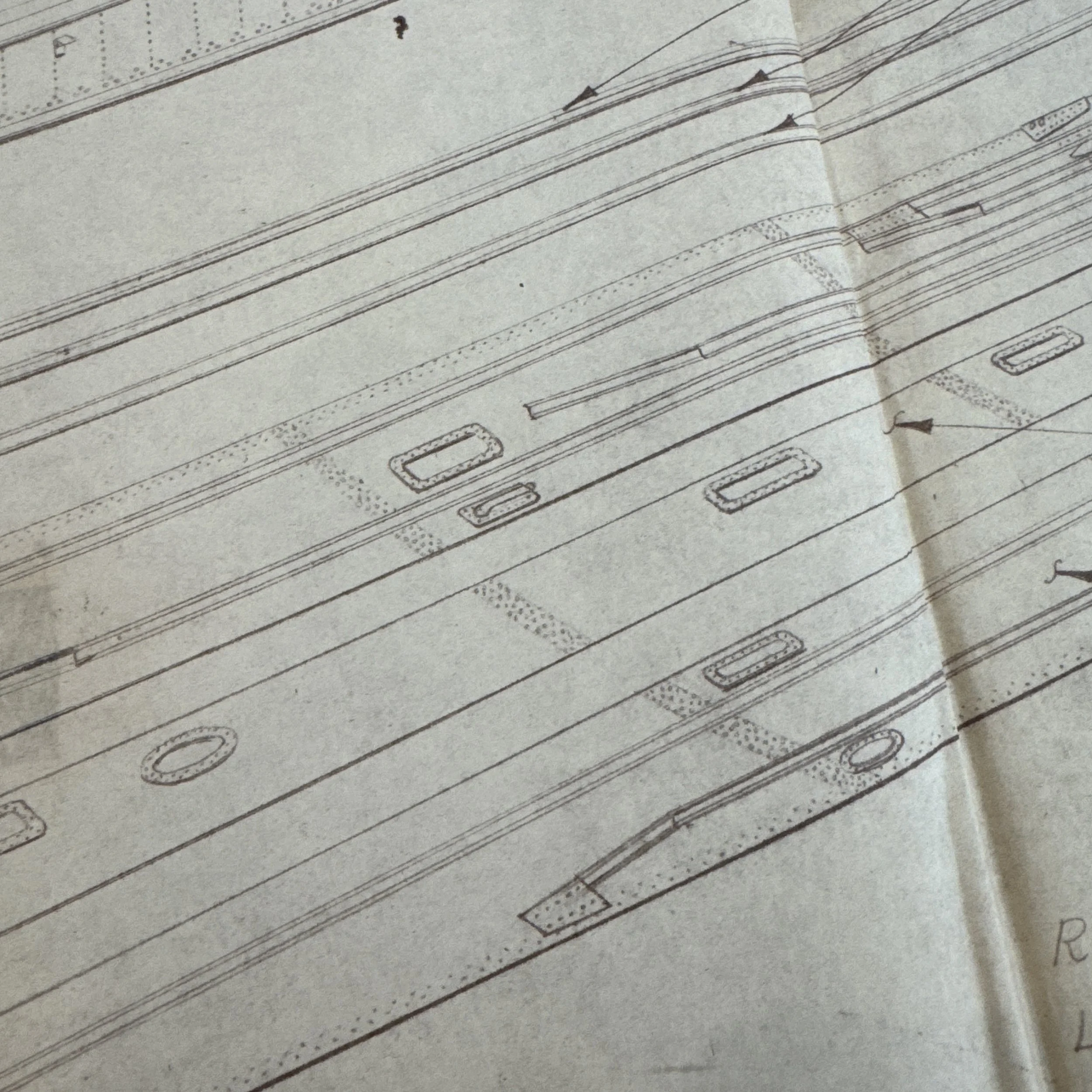

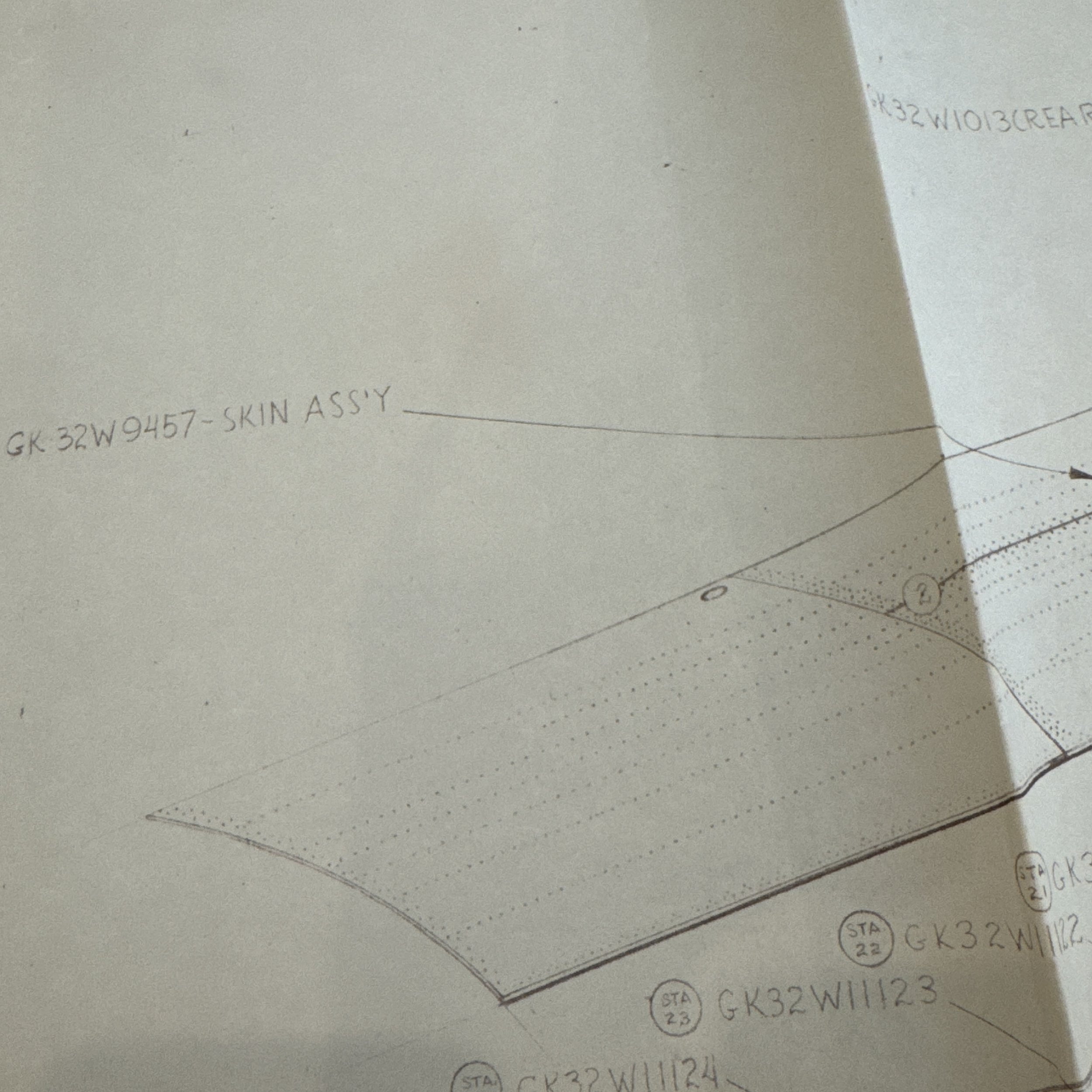

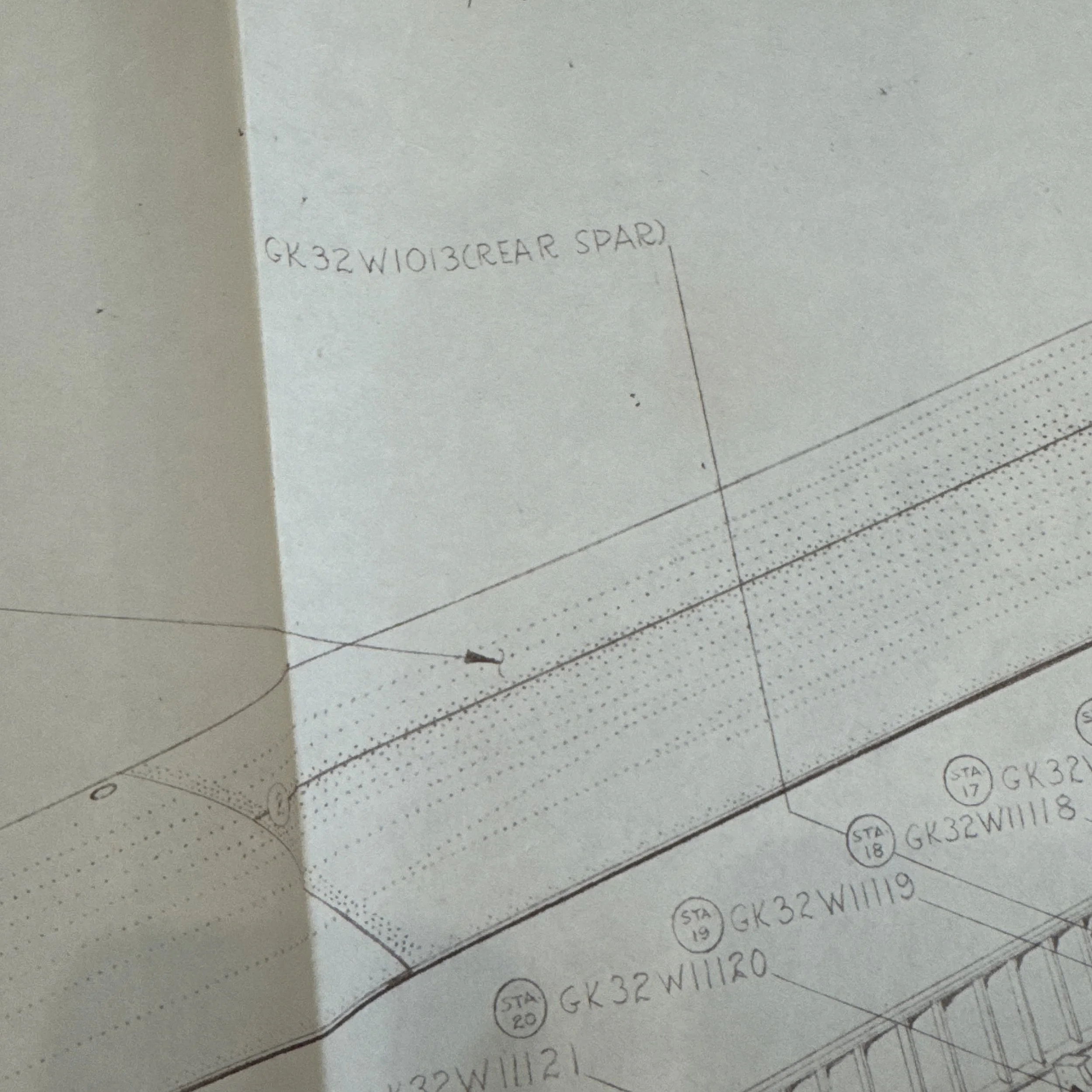

This blueprint documents the complex internal architecture of the Liberator’s wing, including spar placement, rib construction, skin panel integration, and load bearing reinforcement points. While these elements may appear purely technical, they were critical to the aircraft’s ability to carry heavy bomb loads over long distances while enduring combat stress, turbulence, and enemy fire. The B 24’s wing design was central to its long range capability and high cruising speed, and the outer wing section in particular played a vital role in maintaining lift and stability during extended missions over hostile territory.

Beyond its structural importance, this blueprint also reflects a major achievement in wartime manufacturing efficiency. By clearly defining the breakdown of wing components and their precise relationships, Ford Motor Company was able to streamline production across its massive assembly plants. Standardized drawings such as this reduced construction errors, improved consistency between aircraft, and allowed thousands of workers to build complex wings with remarkable speed and accuracy. In practical terms, this meant more bombers reaching the front lines faster during one of the most demanding periods of industrial mobilization in American history.

The outer wing sections were also essential to housing fuel tanks, control surfaces, and internal systems that supported the Liberator’s long range mission profile. Any improvement in wing construction directly affected aircraft endurance, flight performance, and crew safety. This blueprint therefore represents far more than a simple technical diagram. It is a record of wartime problem solving driven by combat experience and the urgent need for reliable, mass produced aircraft.

As a surviving engineering blueprint from December 1943, this artifact captures a precise moment in the evolution of the B 24 Liberator. It reflects the continuous refinement process as engineers balanced structural strength with weight reduction and manufacturing practicality. Very few original wartime aircraft factory blueprints remain outside institutional archives today. Most were discarded after production ended or lost over time. The survival of this document makes it exceptionally rare and historically significant.

In essence, this blueprint is a direct link to the immense industrial and engineering effort that powered Allied air superiority in World War II. It tells the story of how careful design, precise planning, and incremental improvements shaped the aircraft that carried the air war to enemy territory. As a one of a kind wartime engineering illustration for the B 24 Liberator’s wing construction, it stands as a powerful artifact of American ingenuity, technical mastery, and the relentless pursuit of progress during humanity’s most consequential conflict.

• Ford Motor Company and the B-24 Liberator Production Effort

This original engineering blueprint originates from the Ford Motor Company, whose Willow Run plant in Michigan became the largest aircraft manufacturing facility in the world during World War II. Ford revolutionized aircraft production by applying automotive assembly line principles to bomber construction, transforming what had once been a slow and complex hand built process into an unprecedented system of mass production. By 1944, Willow Run was producing a completed B-24 Liberator every sixty three minutes. Ford alone manufactured over 8,600 B 24 aircraft, accounting for nearly half of all Liberators ever built. This blueprint is a direct product of that historic industrial achievement and represents the engineering refinement that allowed Ford to maintain speed, quality, and consistency during the final and most intense years of the war.

• Total Number of B-24 Liberators Produced

The Consolidated B-24 Liberator holds the distinction of being the most produced heavy bomber in aviation history. A total of more than 18,400 B-24 aircraft were manufactured during World War II. Of these, Ford Motor Company produced over 8,600 at Willow Run alone, while the remainder were built by Consolidated in San Diego and Fort Worth, Douglas Aircraft, and North American Aviation. This massive production output made the B 24 the backbone of Allied long range bombing power and a central symbol of American industrial strength during the war.

• Role in Major Battles and Campaigns. 1944 to 1945

From 1944 through 1945, the B-24 Liberator played a central role in many of the most decisive air campaigns of the war. In Europe, B-24s flew as part of the Eighth and Fifteenth Air Forces, conducting strategic bombing missions against German industrial centers, oil refineries, aircraft factories, rail yards, and submarine pens. They participated in Operation Pointblank, the Combined Bomber Offensive, and the sustained bombing campaign that weakened the Luftwaffe and crippled German war production. B-24s also supported the Normandy invasion by attacking transportation networks and coastal defenses in the weeks leading up to and following D-Day. In the Pacific Theater, B-24 Liberators were essential to long range bombing operations against Japanese bases, shipping lanes, and island strongholds. They were heavily used in campaigns across New Guinea, the Philippines, and later against targets in Formosa and mainland Japan. Their long range capability made them particularly valuable in the vast distances of the Pacific war.

• U.S. Squadrons and Air Forces That Used the B-24 During This Period

During 1944 and 1945, B-24 Liberators were flown by numerous U.S. Army Air Forces units across multiple theaters. In Europe, they were operated extensively by the Eighth Air Force based in England and the Fifteenth Air Force based in Italy. Notable Bomb Groups included the 44th Bomb Group, 93rd Bomb Group, 98th Bomb Group, 389th Bomb Group, and the 376th Bomb Group, among many others. These units carried out daily missions deep into enemy territory, often facing intense anti aircraft fire and fighter opposition. In the Pacific, B-24s were flown by the Fifth Air Force, Seventh Air Force, and Thirteenth Air Force. These squadrons conducted long range bombing raids and maritime patrol missions across island chains and open ocean. The aircraft also served with the U.S. Navy and U.S. Army Air Forces in anti submarine roles in the Atlantic, protecting vital supply convoys from German U boats.